- Joined

- Dec 18, 2013

- Messages

- 2,012

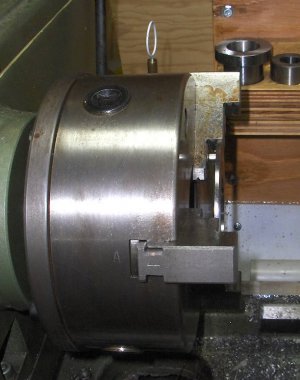

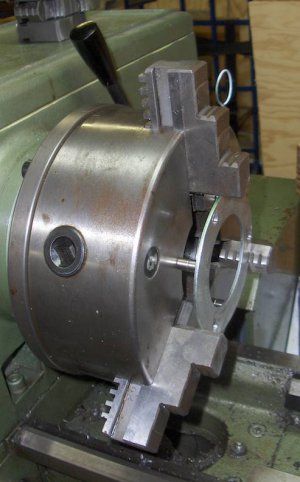

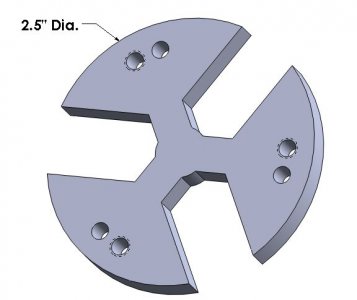

Does anyone have experience with these Royal Products chuck stops? With the 25% off Enco sale going on I can get the set of 5 for $277 which is still pretty expensive but I could choke that down.

Machining soft jaws makes no sense as an alternative, not to machine 1 or 2 parts. I'm looking for something quick and easy for my PBA 8" chuck.

Machining soft jaws makes no sense as an alternative, not to machine 1 or 2 parts. I'm looking for something quick and easy for my PBA 8" chuck.

Last edited by a moderator: