- Joined

- Jul 28, 2017

- Messages

- 2,378

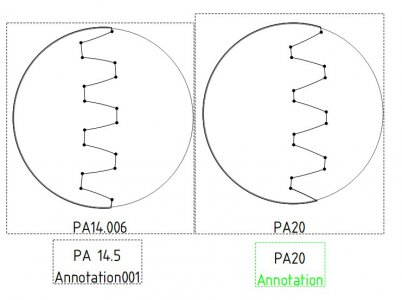

There are a number of CAD programs that can create gears. I know there's a script written for OpenSCAD that can do it. Presumably it allows the user to set the PA along with the tooth count.

For a sightly different approach, McMaster has CAD drawings for many of their parts. Maybe they have drawings you can use for comparison.

For a sightly different approach, McMaster has CAD drawings for many of their parts. Maybe they have drawings you can use for comparison.