- Joined

- Feb 1, 2015

- Messages

- 9,937

i had this very same problem just last week. examine the parting tool very closely. the cutting tip must be the widest part of the parting blade. look closely at the part of the blade that enters the cut after the cutting tip. i bet there is a portion that is wider than the cutting tip and is ''rubbing'' on material u are cutting. if so i guarantee u this will cause a cut that is exactly like the one u are getting. at least that is what i found to be true in my case. good luck--re steve in montana.

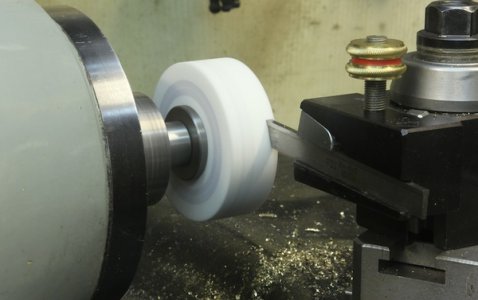

It sounds like everything has been covered. But to recap, a parting tool has by necessity, flex and will yield to unbalanced forces. If the tool is ground at a slight angle, either in error or intentionally to cut the last remaining nub from the part, as David S has suggested, there will a force causing the tool to flex. Similarly, a dull tool, as mentioned can cause these unbalanced forces. You mentioned that you had carefully aligned the tool to be perpendicular to the axis and that your facing cuts a true so you should be able to rule out those as the cause. It is really amazing how little force is required to deflect a parting tool. On occasion, I have used one for facing the right hand side of a narrow groove and even with a few thousandths cut on aluminum, there is deflection.

It is also important to make sure the tool is vertically aligned. Too low and the the tool is scraping rather than cutting; too high and it will catch and be deflected downward and spring back up causing chatter. Mike, above, gives a very good method for vertical alignment.

I have watched You Tube videos of parting with envy as it seems that they part with ease with no chatter, perfectly true cuts, and a mirror finish on the parted piece. It is easy to forget that these are on much larger lathes than I have. Their parting tool is larger and the whole mechanism is more massive and rigid.

One possibility, if nothing else works, would be to offset the tool slightly in the direction opposing the bias you are seeing so when the tool cuts, it will deflect into a perpendicular parting cut. I would not lock down the carriage in that case but allow the tool to follow the cut.