-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- GENERAL TYPES OF METALWORKING MACHINES

- ANTIQUE & VINTAGE MACHINERY

- MISC ANTIQUE & VINTAGE MACHINERY

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Peerless Shaper Followed Me Home

- Thread starter francist

- Start date

F

f350ca

Forum Guest

Register Today

Worked up enough nerve to plug it in tonight. It had a 50 amp 220 v welder plug on the cord. Odd motor on it, no capacitors, makes a funny almost hissing sound as it comes up to speed and as it slows down.

The good news is it moves as it should and relatively quiet. A few mild growls, but its getting quieter as new oil works into the joints and bearings, it apparently hadn't be turned on in 10 years.

Frank, looking at the pictures of yours it amazing how many parts are identically designed only scaled. One neat feature I stumbled on that I think yours has as well. The table wasn't moving, but the gears from the ratchet were, it was missing a key, between the gear and the lead screw to move the table. The gear slides on and off the shaft but can also be put on the lower shaft to power the table up or down for side cuts.

Greg

The good news is it moves as it should and relatively quiet. A few mild growls, but its getting quieter as new oil works into the joints and bearings, it apparently hadn't be turned on in 10 years.

Frank, looking at the pictures of yours it amazing how many parts are identically designed only scaled. One neat feature I stumbled on that I think yours has as well. The table wasn't moving, but the gears from the ratchet were, it was missing a key, between the gear and the lead screw to move the table. The gear slides on and off the shaft but can also be put on the lower shaft to power the table up or down for side cuts.

Greg

A

Andre

Forum Guest

Register Today

The hissing sound could be the centrifugal switch inside the motor, that disconnects the brushes needed to kick start the rotor after it's up to speed.

- Joined

- Sep 5, 2013

- Messages

- 3,207

I wish I could have been there for that, seeing the beast wake up again from ten years of sleep. And I think Andre is right about that hissing noise, I've always liked the sound of the old motors that do that.

Greg you're right about the vertical table advance, mine has it as well. In fact I just stumbled across it last week when I was looking at the micrometer dials. One of them was on backwards with the hash marks facing away from the index line. I wondered why that would happen, and then when I fiddled with that gear to see if it was loose or something it slid right off in my hand. Right about then I had the "aha" moment and twigged to the choice of vertical and horizontal feed. I didn't think that feature was real common, especially on a smaller shaper. It seems to me it would put a lot of load onto the small teeth for the pawl whenever the table+vise+workpiece was being raised like that. I'll not be trying it right away anyway though, there's something not quite right about how my table raises. It's fine at the bottom and fine up towards the top, in the mid-height area it's quite hard to crank up. Like the gears aren't meshing right in that one section for some reason. Have to take it apart a bit to have a better look. Right now I'm still putting the motor and switching back together into the stand so I can run the thing.

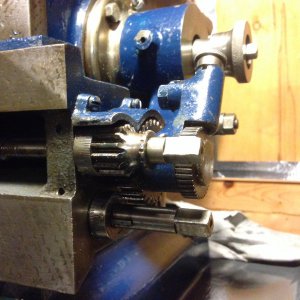

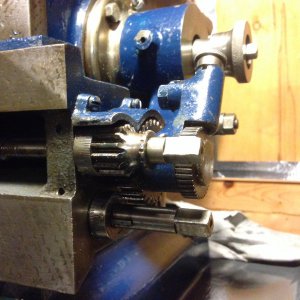

Here's a couple shots of the movable gear.

-frank

Greg you're right about the vertical table advance, mine has it as well. In fact I just stumbled across it last week when I was looking at the micrometer dials. One of them was on backwards with the hash marks facing away from the index line. I wondered why that would happen, and then when I fiddled with that gear to see if it was loose or something it slid right off in my hand. Right about then I had the "aha" moment and twigged to the choice of vertical and horizontal feed. I didn't think that feature was real common, especially on a smaller shaper. It seems to me it would put a lot of load onto the small teeth for the pawl whenever the table+vise+workpiece was being raised like that. I'll not be trying it right away anyway though, there's something not quite right about how my table raises. It's fine at the bottom and fine up towards the top, in the mid-height area it's quite hard to crank up. Like the gears aren't meshing right in that one section for some reason. Have to take it apart a bit to have a better look. Right now I'm still putting the motor and switching back together into the stand so I can run the thing.

Here's a couple shots of the movable gear.

-frank

F

f350ca

Forum Guest

Register Today

The dials on mine are about the same pathetic size as yours. Guess they were space limited with the two shafts if they were going to drive both of them, but that doesn't excuse the even smaller dial they used on the clapper box feed.

The raising mechanism on mine uses two threaded sections, one inside the other to gain the vertical lift required. If yours is the same the stiff intermediate section might be where the second one starts to turn.

Greg

The raising mechanism on mine uses two threaded sections, one inside the other to gain the vertical lift required. If yours is the same the stiff intermediate section might be where the second one starts to turn.

Greg

F

f350ca

Forum Guest

Register Today

Right you are Andre. The motor is in fact a repulsive/inductive motor. The hissing sound is the brushes running on the commentator, once up to speed they are pulled sideways to clear.

Frank, this is the two piece jack screw I mentioned.

Sorry for taking up your thread, will start a new one when I get to cleaning the old girl up.

Greg

Frank, this is the two piece jack screw I mentioned.

Sorry for taking up your thread, will start a new one when I get to cleaning the old girl up.

Greg