- Joined

- Feb 24, 2015

- Messages

- 1,382

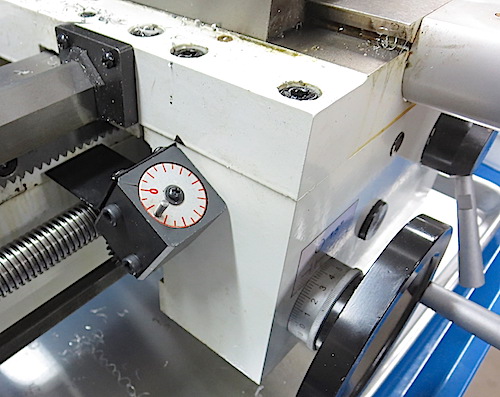

The thread chasing dial arrived yesterday. It attaches to two little holes on the left side of the saddle that were plugged with set screws. It didn't come with attaching bolts or any instructions what so ever. The bolts were 5mm. I had to purchase 50mm bolts and cut them down to about 45mm.

Other than having to modify a couple bolts, the installation went easily.

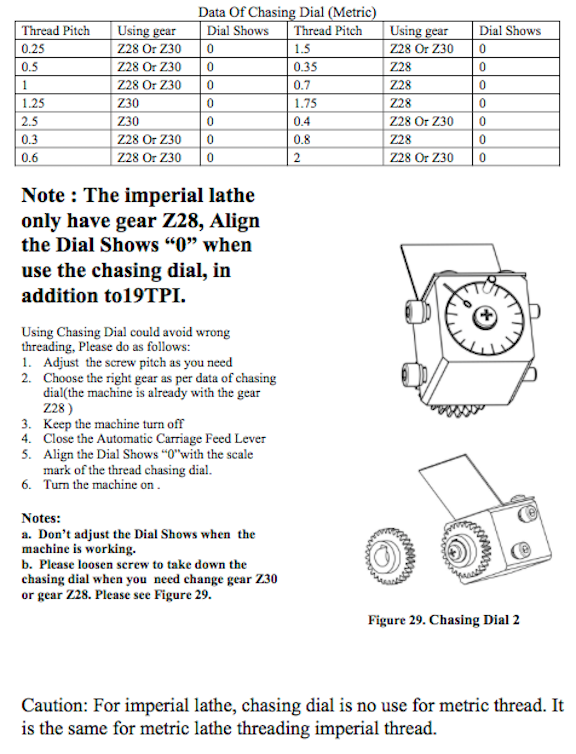

I have absolutely no idea how to operate it. Matt sent me some instructions.

As near as I can tell, it says to do all imperial threading from zero on the dial.

For metric threads the dial won't work without the other gear it didn't come with.

Other than having to modify a couple bolts, the installation went easily.

I have absolutely no idea how to operate it. Matt sent me some instructions.

As near as I can tell, it says to do all imperial threading from zero on the dial.

For metric threads the dial won't work without the other gear it didn't come with.