- Joined

- Feb 27, 2014

- Messages

- 2,129

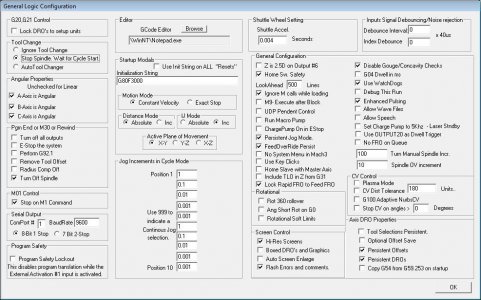

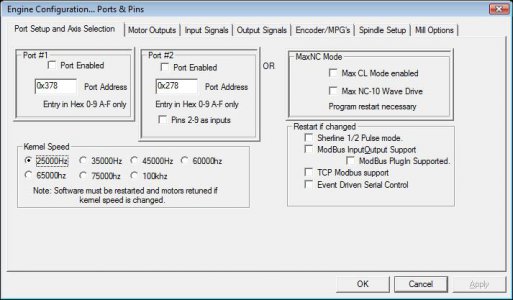

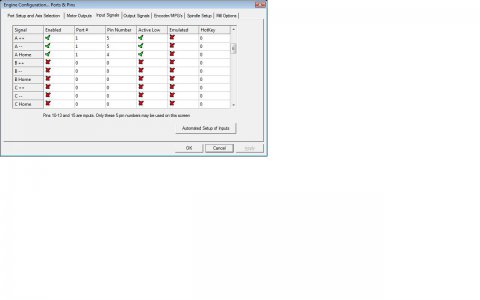

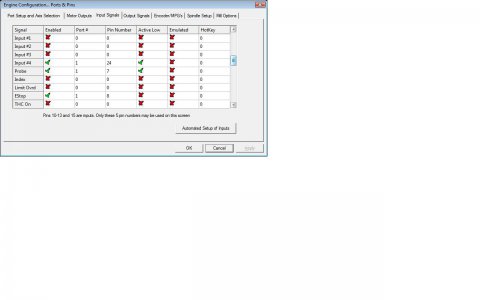

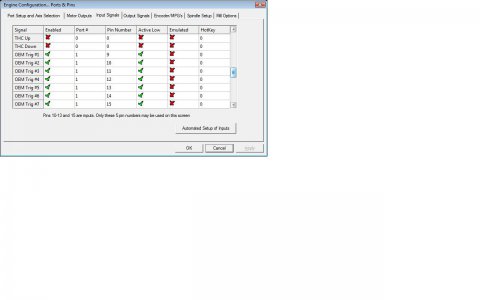

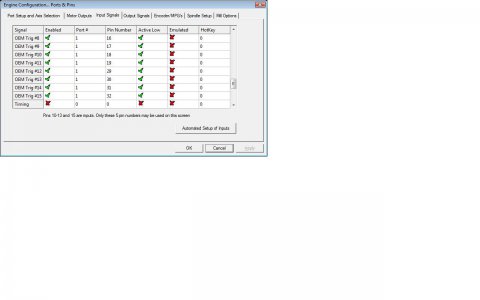

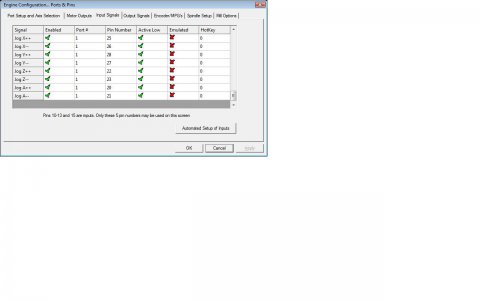

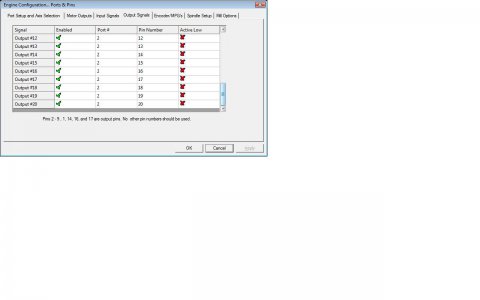

I figured we could use a thread specific to configuration of the Precision Mathews 45M-CNC. This will make it easier for people to find from searches in the future.

I have attached my XML configuration file. I am not sure if it is directly interchangeable with other systems but likely it is with the one issue that I have the PBJ Multi Interface ScreenSet 2013 installed.

Just put this in the MACH3 directory and it should show up in the list of systems when you use the Mach3 loader.View attachment PM-45M-CNC.xml

I have attached my XML configuration file. I am not sure if it is directly interchangeable with other systems but likely it is with the one issue that I have the PBJ Multi Interface ScreenSet 2013 installed.

Just put this in the MACH3 directory and it should show up in the list of systems when you use the Mach3 loader.View attachment PM-45M-CNC.xml