- Joined

- Oct 30, 2019

- Messages

- 197

Hi all, this is an area where I am normally in my comfort zone but this issue is odd enough that I have run out of ideas and ruled out the causes that make sense to me. Take any of my reasoning, editorializing, leaps or conclusions below with a grain of salt, since I clearly am missing something and not capable of solving/fixing this problem yet.

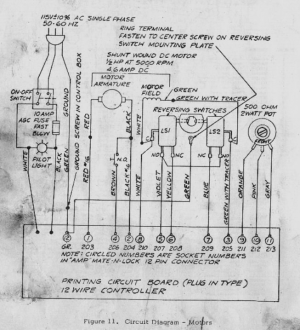

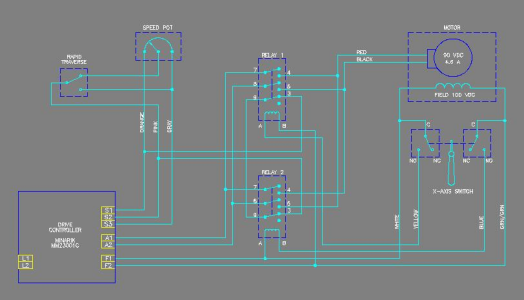

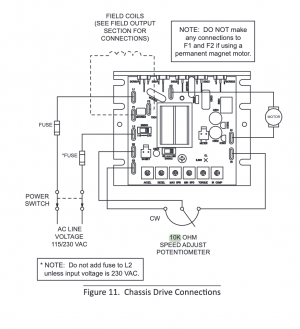

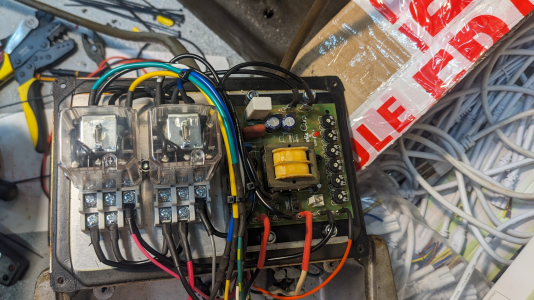

I just finished setting up a new drive for my Bridgeport's 6F x-axis powerfeed, using a Minarik drive and the guidance provided at https://www.atechfabrication.com/information/Bridgeport_Feed_Controller.htm

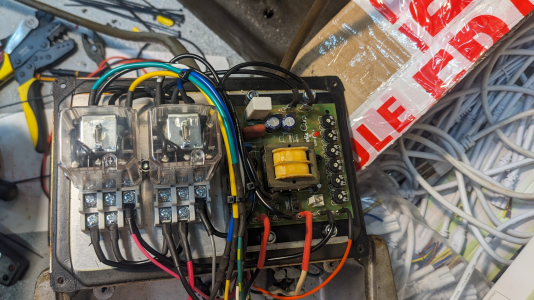

All looked and worked great, so I buttoned up the enclosures and mounted everything back together.

When testing again after fully mechanical assembly, I found the following symptom:

I have a demonstration and explanation of the issue in the video below:

Troubleshooting I've done so far:

Thanks for any guidance or brainstorming that might be offered

I just finished setting up a new drive for my Bridgeport's 6F x-axis powerfeed, using a Minarik drive and the guidance provided at https://www.atechfabrication.com/information/Bridgeport_Feed_Controller.htm

All looked and worked great, so I buttoned up the enclosures and mounted everything back together.

When testing again after fully mechanical assembly, I found the following symptom:

- Instead of soft starting, the motor would "bump" a bit, stop, then slow-start. The drive appears to otherwise operate normally

- This symptom would only happen when the 10k (linear taper, 2 watt) potentiometer was mounted in the panel, and the panel mounted in the motor housing (which is grounded along with the rest of the machine)

- If the potentiometer or panel were floating free in space, everything behaves 100% normally

- One time while testing it (perhaps at higher speed), it actually tripped the GFCI breaker for the circuit in the shop that this is plugged into

- I measure maybe 60 vollts DC (the relay coils and field windings happen to be 110VDC) from the pot to ground when it is floating, but very very low current - like 5 microamps. The potentiometer itself is only fed ~.7 vdc

- One time I was touching the pot with my hand and my nose brushed against something on the head of the mill, and I felt what felt like a static shock. This seems to align with a very small leakage current building up a charge on the potentiometer that is discharging. I did not care to reproduce this observation/symptom

- The control panel has a button for rapid traverse, but no leads are currently connected to it, so only the potentiometer seems to be in-scope

I have a demonstration and explanation of the issue in the video below:

Troubleshooting I've done so far:

- Tested the potentiometer for leakage paths from the resistive element and wiper to its case/ground and found nothing, all open (tested with a ~20 megohm DMM)

- Replaced the potentiometer with an identical one (I bought two at the same time); same behavior

- Verified that none of the control wiring between the drive housing and the motor has a short to ground. This wouldn't really make sense anyway, since it very clearly is only happening when the metal pot housing is grounded, meaning the wiring should be excluded

- Per recommendations in the Minarik drive's manual, I twisted the potentiometer wiring (S1,S2,S3 in the diagram linked above) together

- I also added an extra ground jumper from an unpainted portion of the drive's board straight to the ground lug on the enclosure, in case the paint plus rubber seal on the back panel were not allowing a clear enough path

- Replacing the pot with a different make/model from a different manufacturer, just in case it is something subtle about its electrical characteristics that are causing this. The current potentiometer is a Centralab RV4NAYSD103A

- Running a separate 3-lead conductor from the motor/controls housing back to the drive enclosure, in case something is picking up interference from the power conductors in the OEM cable assembly. I would be surprised if this was the case, since I can't come up with an explanation for why this would only be the issue when the pot case is grounded.

Thanks for any guidance or brainstorming that might be offered

Last edited: