- Joined

- May 16, 2016

- Messages

- 194

The mill uses 4PN collets, not the easiest to find. But they do pop up on eBay, so I will keep my eyes open.

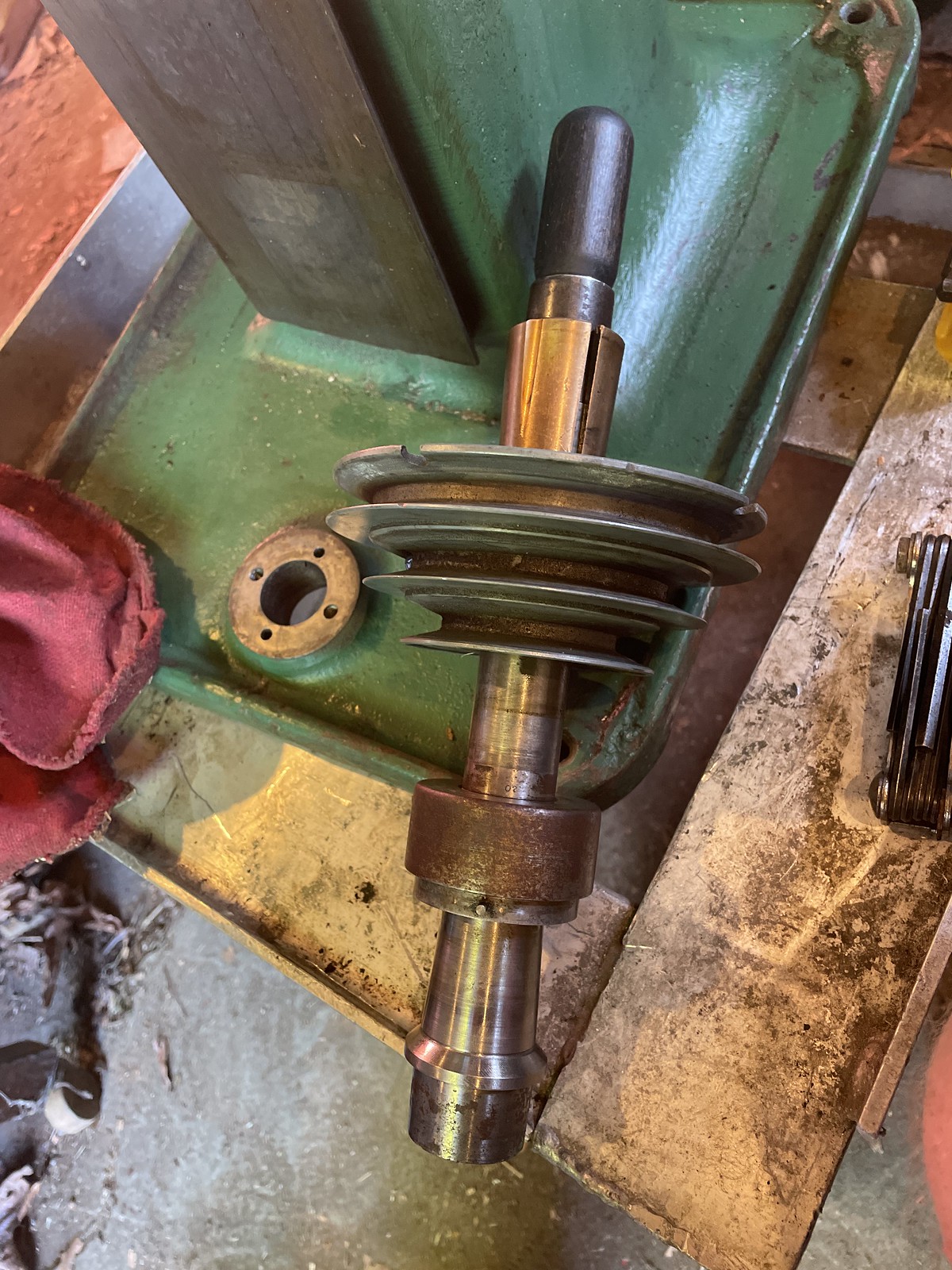

I decided to just remove the whole knee, and bring that into my shop for further disassembly, as it is easier if I can see from all angles how some parts of it will disassemble.

and another angle

The object to the left of it came with it when purchased, and I thought it was the original dividing head, but now I am not so sure, as it isn't set up to fit in the table's slot.

And here is all the parts I have already removed

I have the feeling that there is no parts interchange between the 3 and 3C models of this, and I really wish I had some sort of parts diagram.

I decided to just remove the whole knee, and bring that into my shop for further disassembly, as it is easier if I can see from all angles how some parts of it will disassemble.

and another angle

The object to the left of it came with it when purchased, and I thought it was the original dividing head, but now I am not so sure, as it isn't set up to fit in the table's slot.

And here is all the parts I have already removed

I have the feeling that there is no parts interchange between the 3 and 3C models of this, and I really wish I had some sort of parts diagram.