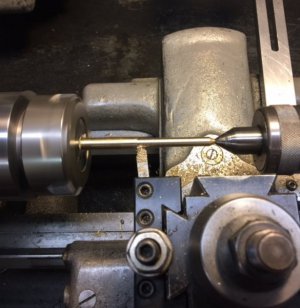

Quite a while back I built my version of John Moran's ( aka: gadgetbuilder ) drill sharpener. While the machine I built works great , I got to thinking, since I built it , I have more and better equipment, much better and more tooling. I want to build another one with a more powerful motor to make sharpening larger drills easier and I want to hold tighter tolerances. The construction of my first machine was mostly aluminum, but I want to make the new one all steel. I was also considering making it an attachment for my newest T&C grinder but that is still up in the air. ( if I make it a stand alone machine I can use it on the bench sitting on my stool or in my wheel chair.)

So....... I started today.

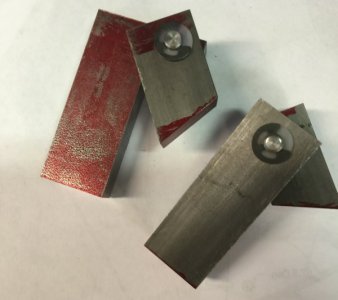

I started with the trunion supports since they are most difficult. These pieces have to be exactly the same height for each pair.

I started with the trunion supports since they are most difficult. These pieces have to be exactly the same height for each pair.

The bearing holes have to be reamed as exact as possible to be in line. Any misalignment and they will bind. I milled them from cold finish steel.

The bearing holes have to be reamed as exact as possible to be in line. Any misalignment and they will bind. I milled them from cold finish steel.

They came out great. I made pins from .250 drill rod and put nylon washers and "e" clips to hold them together. ( the original had tapped holes and screws in the ends of the pins) , I like this better. This and mounting these is the most critical and difficult part. I have ordered some steel plate to finish the trunion assembly...... More to come.

They came out great. I made pins from .250 drill rod and put nylon washers and "e" clips to hold them together. ( the original had tapped holes and screws in the ends of the pins) , I like this better. This and mounting these is the most critical and difficult part. I have ordered some steel plate to finish the trunion assembly...... More to come.

So....... I started today.

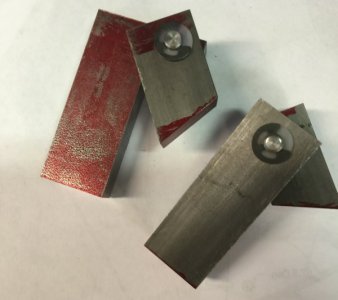

I started with the trunion supports since they are most difficult. These pieces have to be exactly the same height for each pair.

I started with the trunion supports since they are most difficult. These pieces have to be exactly the same height for each pair. The bearing holes have to be reamed as exact as possible to be in line. Any misalignment and they will bind. I milled them from cold finish steel.

The bearing holes have to be reamed as exact as possible to be in line. Any misalignment and they will bind. I milled them from cold finish steel. They came out great. I made pins from .250 drill rod and put nylon washers and "e" clips to hold them together. ( the original had tapped holes and screws in the ends of the pins) , I like this better. This and mounting these is the most critical and difficult part. I have ordered some steel plate to finish the trunion assembly...... More to come.

They came out great. I made pins from .250 drill rod and put nylon washers and "e" clips to hold them together. ( the original had tapped holes and screws in the ends of the pins) , I like this better. This and mounting these is the most critical and difficult part. I have ordered some steel plate to finish the trunion assembly...... More to come.