- Joined

- Feb 5, 2015

- Messages

- 662

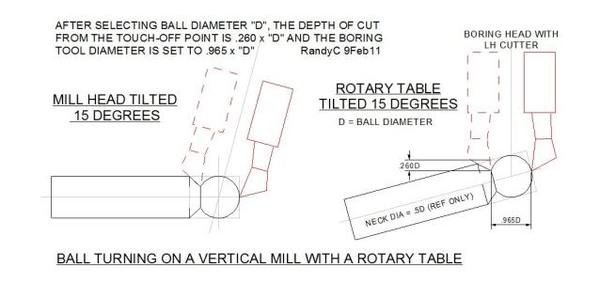

I posted a method of producing small ball configurations on a vertical mill in a previous thread regarding various setups for a rotary table. This method might be useful to a few people (telescope guys, maybe). I'm not sure that this is the correct place to post this but I couldn't think of a more appropriate one...

This is an experiment that I tried a few years ago following another interesting experiment to learn how to produce large concave surfaces on a lathe or a vertical mill.

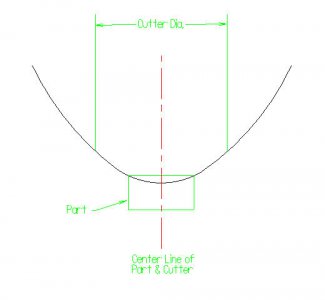

Tilting the head of the mill (or the rotary table) to a specific angle and adjusting the “stickout” of a flycutter, one can produce a fairly precise concave surface. Errors in the radius caused by runout in the mill spindle or rotab bearing are averaged out with multiple passes.

The flycutter is SLOWLY advanced into the work with minimal DOC and the rotary table is then rotated through a full turn(s) until the full depth is nearly reached. Final cut should be multiple revolutions to average errors.

It is an exercise in descriptive geometry to determine the starting parameters. One of these days I’ll make a spreadsheet to determine them. I suspect that making a CAD layout would be lots faster

PS I'm too impulsive about spelling and construction otherwise I wouldn't have to edit !

This is an experiment that I tried a few years ago following another interesting experiment to learn how to produce large concave surfaces on a lathe or a vertical mill.

Tilting the head of the mill (or the rotary table) to a specific angle and adjusting the “stickout” of a flycutter, one can produce a fairly precise concave surface. Errors in the radius caused by runout in the mill spindle or rotab bearing are averaged out with multiple passes.

The flycutter is SLOWLY advanced into the work with minimal DOC and the rotary table is then rotated through a full turn(s) until the full depth is nearly reached. Final cut should be multiple revolutions to average errors.

It is an exercise in descriptive geometry to determine the starting parameters. One of these days I’ll make a spreadsheet to determine them. I suspect that making a CAD layout would be lots faster

PS I'm too impulsive about spelling and construction otherwise I wouldn't have to edit !

Last edited: