- Joined

- Aug 4, 2023

- Messages

- 78

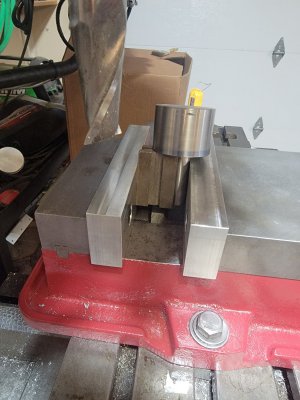

Welp, here she is, le piece de resistance.

When I fist chucked it up in the mill it had about .010 runout. This is probably for to me only having a 3 jaw chuck and not turning with centers. I put it back on the lathe and shaved off about .012. I know my mill is good for a half thou runout and I can always count on the lathe for at least a thou. In the end I got it to spin with a hair under .002 runout in the mill. I figure this is probably fine. All i could do to improve it further would be to turn the body once more using the mill itself. Probably overkill, but its its an option should I need it.

Only thing left now is to grind a tool and give it a whirl. I'm debating on whether to blue it or not.

When I fist chucked it up in the mill it had about .010 runout. This is probably for to me only having a 3 jaw chuck and not turning with centers. I put it back on the lathe and shaved off about .012. I know my mill is good for a half thou runout and I can always count on the lathe for at least a thou. In the end I got it to spin with a hair under .002 runout in the mill. I figure this is probably fine. All i could do to improve it further would be to turn the body once more using the mill itself. Probably overkill, but its its an option should I need it.

Only thing left now is to grind a tool and give it a whirl. I'm debating on whether to blue it or not.