I have slowly been adding to my collection of AXA style tool holders and it has become necessary to better organize them. The small size of my work area precluded a wall mounted storage unit.

I decided that a rack mounted at the top of the backsplash wouldn't be too much in the way of machining and tools would be readily accessible. The plan was to make vertical hangers for the tool holders which would provide the densest storage. I could store 1`6 tool holders across the backsplash. In addition, I added four holders for MT3 tooling.

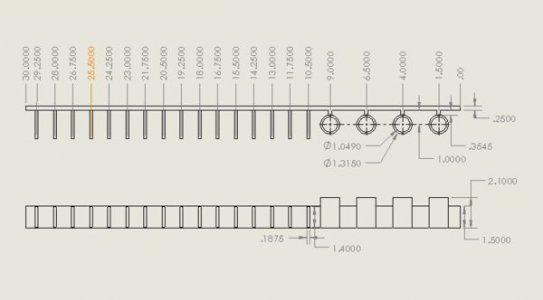

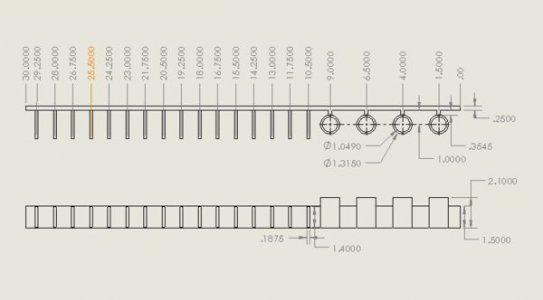

For the base of the rack, I used a 30" piece of 1/4" x 1,-1/2" hot rolled steel. For the hangers, I cut 1.40" pieces of 3/16" x 2" hot rolled. Four standoffs for the MT3 sockets were cut from 1`/4" x 3/8" hot rolled bar.

The MT3 holders were cut from 1`" Sch. 40 galvanized pipe. I burned off most of the galvanizing in my wood furnace. The temperature has to get up to about 1200ºF where the zinc burn off with a bright greenish white flame. When most of the galvanizing had burn3ed off, I dissolved the remainder with muriatic acid. Scale and rust on the hot rolled pieces was partially dissolved in EvapoRust and completed with muriatic acid, leaving clean steel.

The standoffs were welded to the pipe segments and the assemblies were tacked to the base. A jig was made to maintain a 1-1/16" spacing between the hangers. The alignment was checked for square and the hangers were welded to the baseplate, each one referencing the4 previous on, until all sixteen had been welded. The assembly was cleaned up and four 1/4" mounting holes were drilled. The weather is still too cold for painting outside so the rack was mounted as-is. It will be easy enough to remove it for painting at a later date.

While this was specifically designed for the Grizzly G0602, with some modification, it is adaptable to a wide variety of applications.

I decided that a rack mounted at the top of the backsplash wouldn't be too much in the way of machining and tools would be readily accessible. The plan was to make vertical hangers for the tool holders which would provide the densest storage. I could store 1`6 tool holders across the backsplash. In addition, I added four holders for MT3 tooling.

For the base of the rack, I used a 30" piece of 1/4" x 1,-1/2" hot rolled steel. For the hangers, I cut 1.40" pieces of 3/16" x 2" hot rolled. Four standoffs for the MT3 sockets were cut from 1`/4" x 3/8" hot rolled bar.

The MT3 holders were cut from 1`" Sch. 40 galvanized pipe. I burned off most of the galvanizing in my wood furnace. The temperature has to get up to about 1200ºF where the zinc burn off with a bright greenish white flame. When most of the galvanizing had burn3ed off, I dissolved the remainder with muriatic acid. Scale and rust on the hot rolled pieces was partially dissolved in EvapoRust and completed with muriatic acid, leaving clean steel.

The standoffs were welded to the pipe segments and the assemblies were tacked to the base. A jig was made to maintain a 1-1/16" spacing between the hangers. The alignment was checked for square and the hangers were welded to the baseplate, each one referencing the4 previous on, until all sixteen had been welded. The assembly was cleaned up and four 1/4" mounting holes were drilled. The weather is still too cold for painting outside so the rack was mounted as-is. It will be easy enough to remove it for painting at a later date.

While this was specifically designed for the Grizzly G0602, with some modification, it is adaptable to a wide variety of applications.