- Joined

- Jun 12, 2014

- Messages

- 5,063

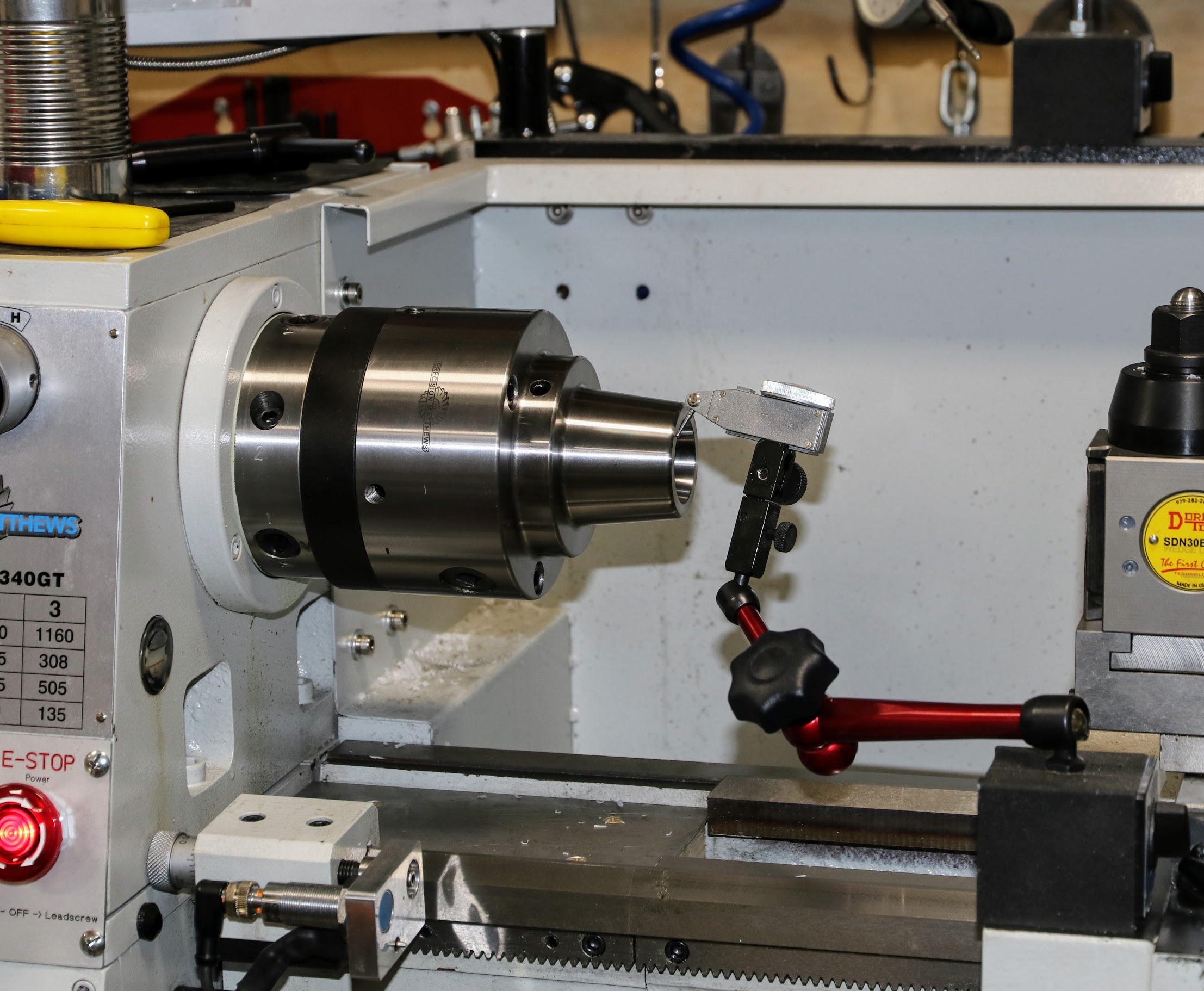

Looks like QMT/Precision Mathews is now stocking high quality adjustable (set-true style) ER-40 and 5C chucks with either D1-4 or D1-5 back plates. I have seen the 5C version (also posted a picture he sent me) and it is very nicely machined, either is a nice addition if you use collet chucks and want a higher quality chuck that won't bust the piggy bank.

HIGH PRECISION ADJUSTABLE ER-40 ER COLLET CHUCK, D1-4 MOUNT FOR METAL LATHE | eBay

HIGH PRECISION, ADJUSTABLE ER-40 COLLET CHUCK, WITH D1-4 MOUNT. A big upgrade from most standard non-adjustable collet chucks, but a very reasonable price. D1-4 Camlock Mounting fits any lathe spindle with this mount.

www.ebay.com

HIGH PRECISION ADJUSTABLE ER-40 ER COLLET CHUCK, D1-5 MOUNT FOR METAL LATHE | eBay

HIGH PRECISION, ADJUSTABLE ER-40 COLLET CHUCK, WITH D1-5 MOUNT. A big upgrade from most standard non-adjustable collet chucks, but a very reasonable price. D1-5 Camlock Mounting fits any lathe spindle with this mount.

www.ebay.com

HIGH PRECISION ADJUSTABLE 5C 5-C COLLET CHUCK, D1-4 MOUNT FOR METAL LATHE | eBay

Find many great new & used options and get the best deals for HIGH PRECISION ADJUSTABLE 5C 5-C COLLET CHUCK, D1-4 MOUNT FOR METAL LATHE at the best online prices at eBay! Free shipping for many products!

www.ebay.com

HIGH PRECISION ADJUSTABLE 5C 5-C COLLET CHUCK, D1-5 MOUNT FOR METAL LATHE | eBay

HIGH PRECISION, ADJUSTABLE 5C COLLET CHUCK, WITH D1-5 MOUNT. A big upgrade from most standard non-adjustable collet chucks, but a very reasonable price. D1-5 Camlock Mounting fits any lathe spindle with this mount.

www.ebay.com