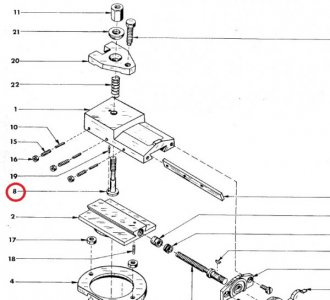

I recently purchased an old Emco Compact 8 lathe and would like to purchase a quick-change tool post. This is the tool post on the machine at present:

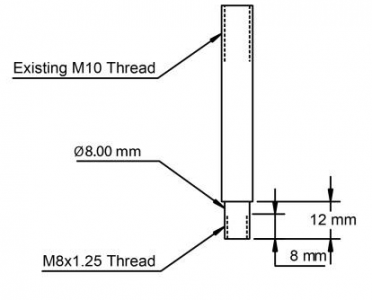

It clamps well, however it requires both the center bolt as well as the clamping bolt to be adjusted, I would prefer something like the one shown below:

I'm looking for recommendations for a suitable one the same or similar to the one above as well as where to purchase.

It clamps well, however it requires both the center bolt as well as the clamping bolt to be adjusted, I would prefer something like the one shown below:

I'm looking for recommendations for a suitable one the same or similar to the one above as well as where to purchase.