Hey guys I’m a local Long Island NY, hobbyist who needs to have the ways and gibs scraped on my table, they came from the factory unmated/unscrapped.

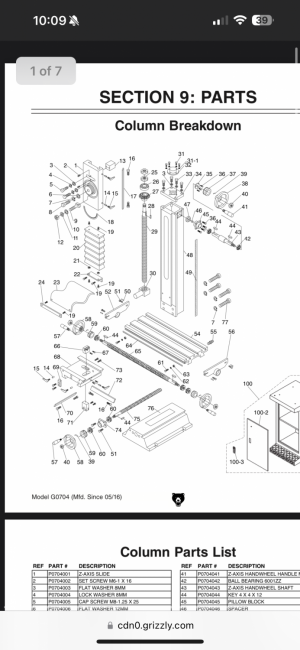

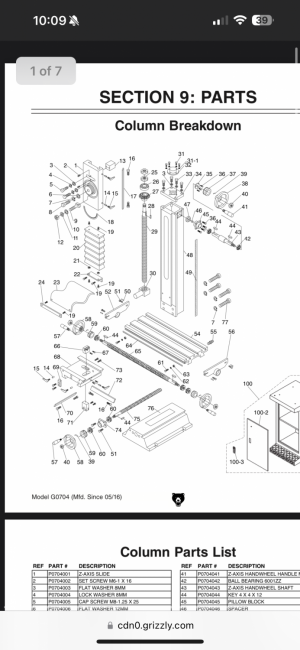

The mill I have is the: G0704

I purchased it to do a cnc upgrade and I don’t really have the ability to scrape it myself. I don’t think I have the time or patience to dedicate to scraping.

How much would a job like this cost? Would it end up being more than what the machine is worth?

If so would you be able to kindly point me in the right direction on what you think the best course of action would be.

Would be great if I could find somebody local, started sending out feelers, but don’t mind shipping either since the parts aren’t relatively that heavy.

Right now I have a $2k paper weight and need to have this done.

Need parts 1, 48, 68, 54, 76 scrapped

The mill I have is the: G0704

I purchased it to do a cnc upgrade and I don’t really have the ability to scrape it myself. I don’t think I have the time or patience to dedicate to scraping.

How much would a job like this cost? Would it end up being more than what the machine is worth?

If so would you be able to kindly point me in the right direction on what you think the best course of action would be.

Would be great if I could find somebody local, started sending out feelers, but don’t mind shipping either since the parts aren’t relatively that heavy.

Right now I have a $2k paper weight and need to have this done.

Need parts 1, 48, 68, 54, 76 scrapped