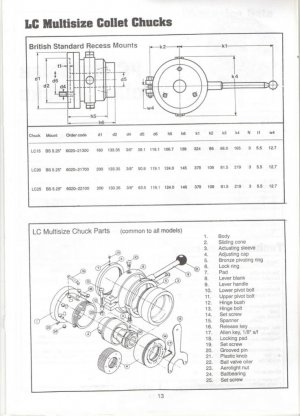

I have been wanting a large collet chuck (larger than the ER40 I already have) for a while, and I finally bought a Pratt Burnerd LC-15 (lever closed) EC collet chuck and set of EC (mostly; one MC) collets. The 1.5" capacity is pretty close to the spindle bore on my G0709.

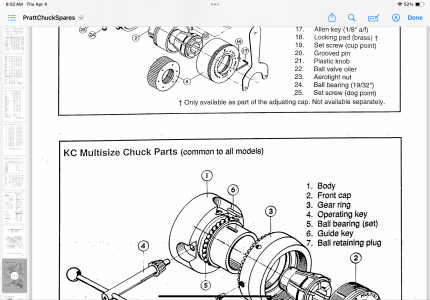

It has some surface corrosion, but the real problem is that it is frozen solid. I cannot turn the cap on the nose.

I have retaining compound curing now in a shop expedient 3" pin wrench to try to remove the cap from the nose and start disassembling it for deep cleaning. I have coated it inside and out with aviation corrosionX because that's supposed to work in and detach corrosion eventually, but with the tight tolerances on the PB chucks that might not be super quick.

The chuck was sold as functional, so if I can't get it working in the next two weeks, I guess I'll be sad and return it to the seller. But I'd rather get it working.

If there is anyone here with experience with any PB LC collet I'd love to get advice.

It has some surface corrosion, but the real problem is that it is frozen solid. I cannot turn the cap on the nose.

I have retaining compound curing now in a shop expedient 3" pin wrench to try to remove the cap from the nose and start disassembling it for deep cleaning. I have coated it inside and out with aviation corrosionX because that's supposed to work in and detach corrosion eventually, but with the tight tolerances on the PB chucks that might not be super quick.

The chuck was sold as functional, so if I can't get it working in the next two weeks, I guess I'll be sad and return it to the seller. But I'd rather get it working.

If there is anyone here with experience with any PB LC collet I'd love to get advice.