- Joined

- Jul 6, 2022

- Messages

- 498

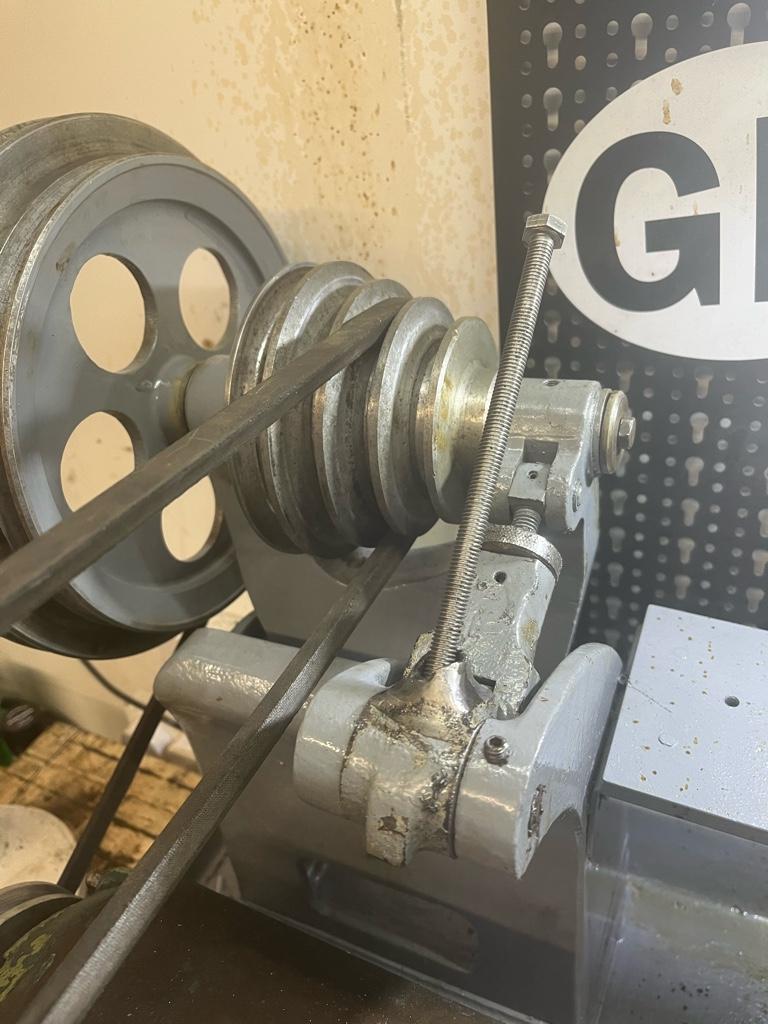

Typically the tailstock is slightly higher than the headstock to allow for some wear. There are no height adjustments in most lathes. Only way to adjust the height downward is to machine the tailstock which is doable but tricky to get right. My mini-lathe is similarly high. My 10x22 is closer to the correct height.

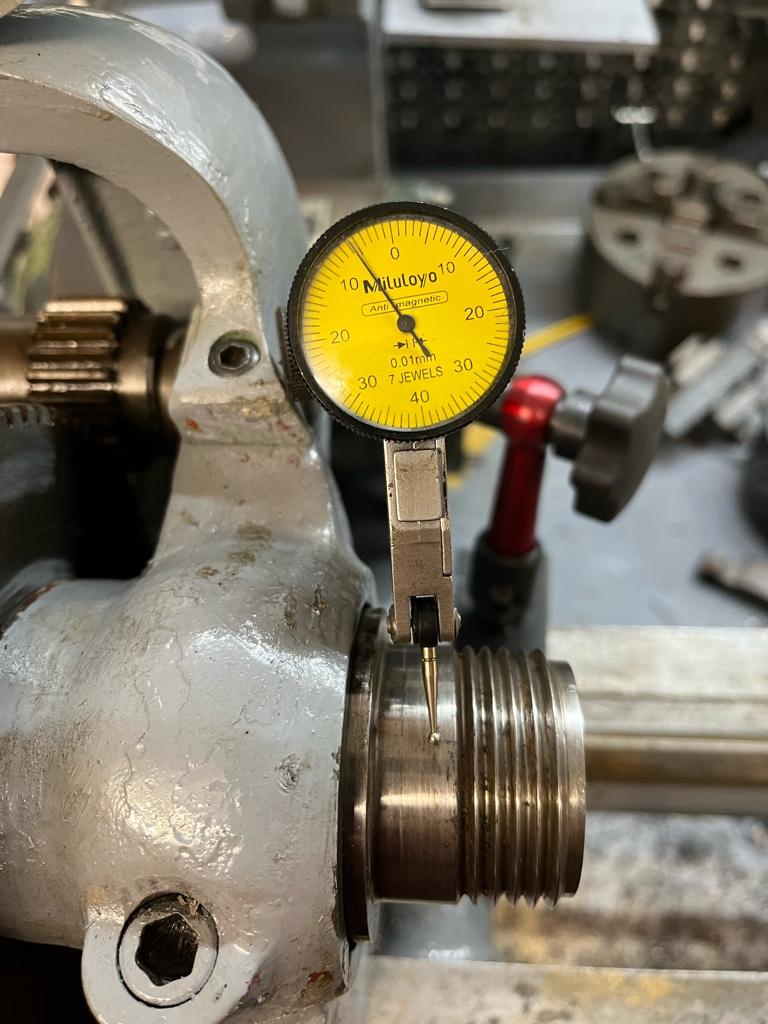

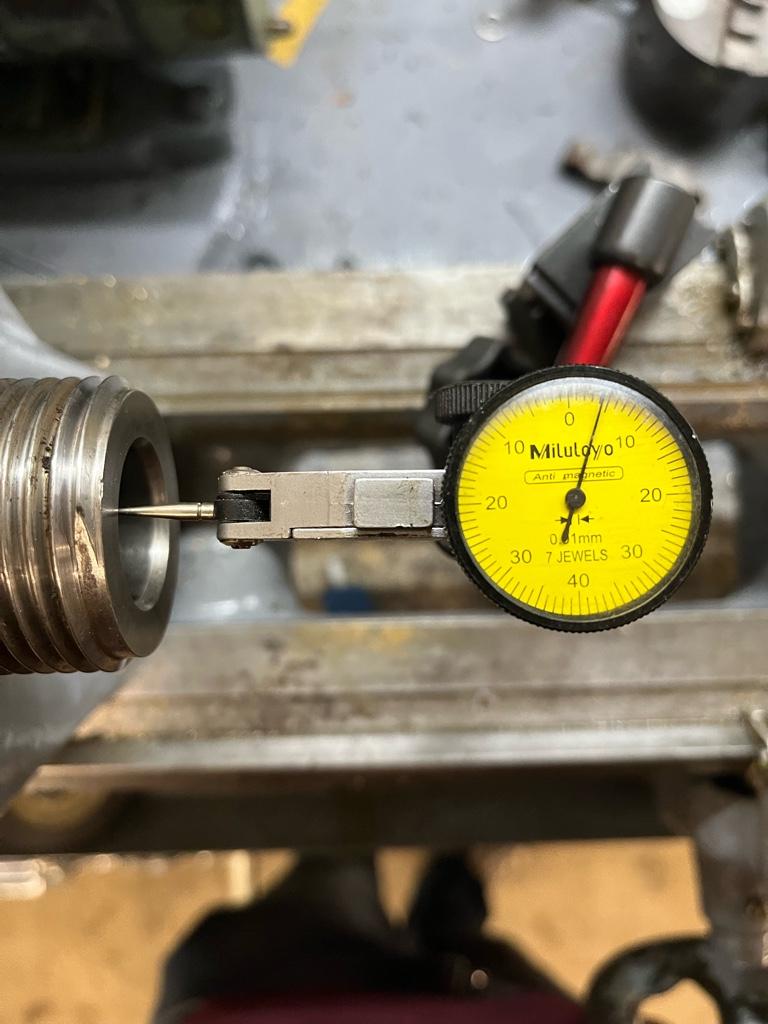

In most cases, the best you can do is to adjust the horizontal offset to zero and live with it. But us being tinkerers we should be able to machine it to get it right. The risk is adding more error than before. We want to reduce height only but not to add yaw or pitch over the full travel of the quill. It's not that easy since you want the tailstock assembly to be true, but you can't assume that the individual pieces are true at all. My mini-lathe tailstock base is not parallel to the ways but the assembly seems ok, save for height. I may try to fix it, since I can get replacement parts if mess it up too much. Not sure about your lathe.

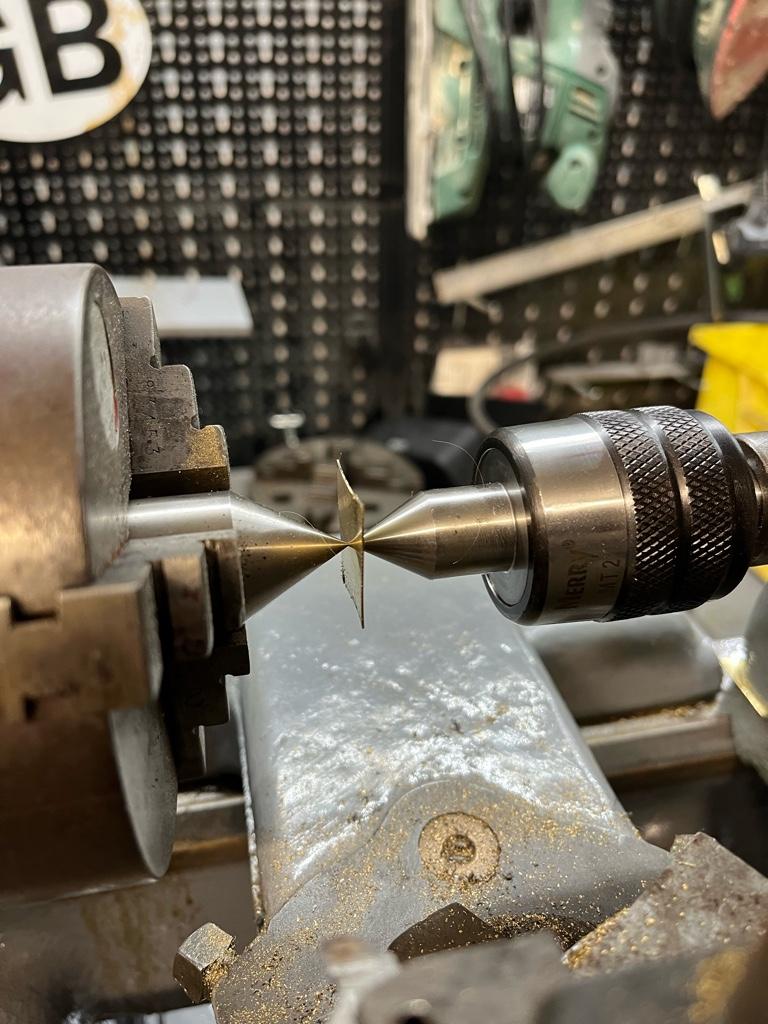

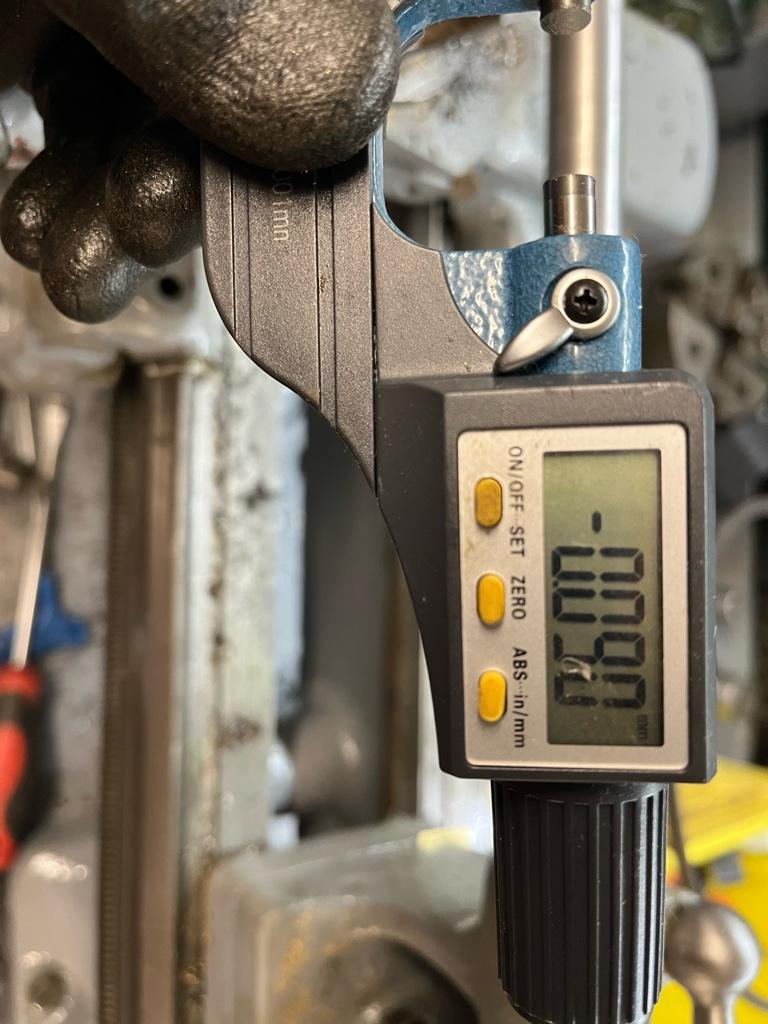

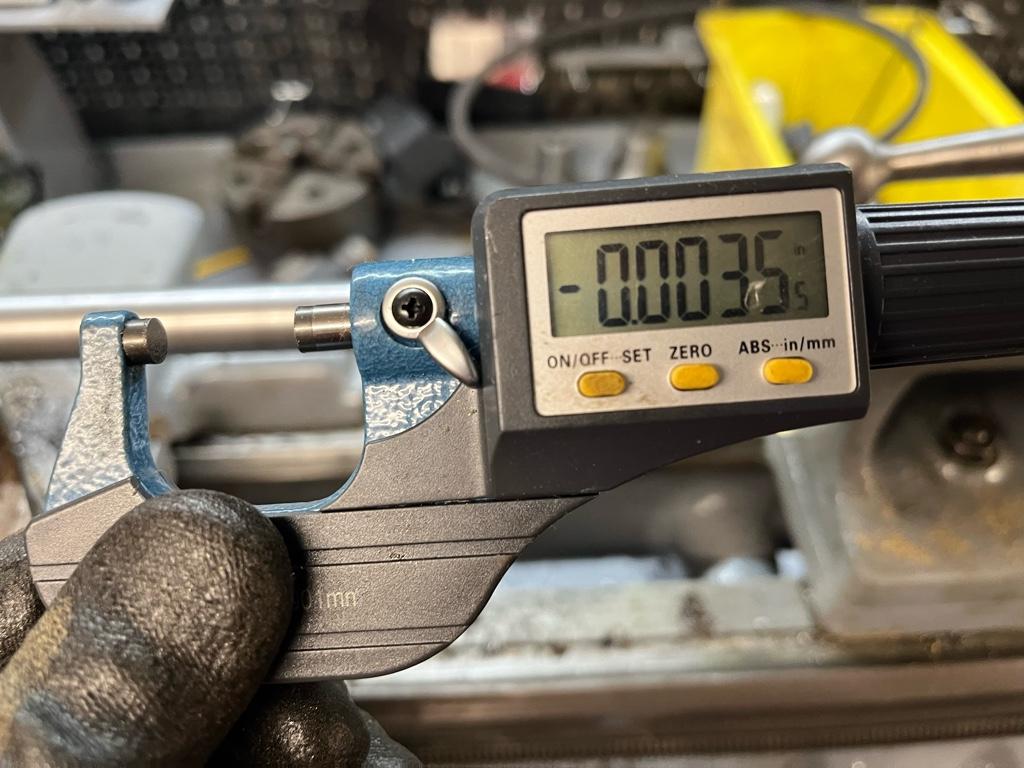

Thanks WobblyHand. I think the picture isn’t too clear, but the tail stock is low here. I’ve read that you can adjust the tail stock up by shimming between the two parts of the tail stock, but I wanted to figure out how to find out if the headstock is level (I’ve had it off the bed whilst restoring). I guess I can indicate the top of the spindle whilst the base is on the ways?

(On a side note, shim stock seems expensive!!?! Maybe just in the UK?)

Sent from my iPhone using Tapatalk