- Joined

- Dec 29, 2012

- Messages

- 394

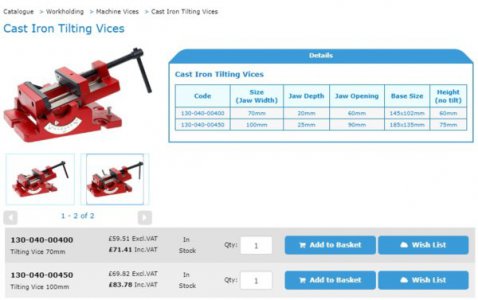

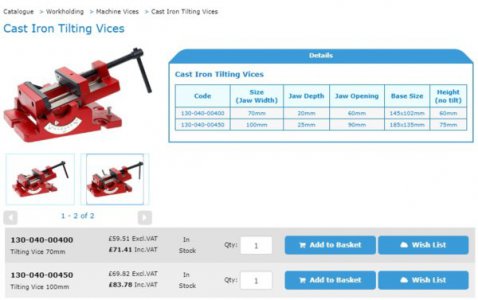

When I bought my mini mill I also bought two small vices (70mm) to hold my work on it.

One of them was a cast iron tilting machine vice.

Jaw opening, dimensions and the looks of it (I thought) was appropriate for the work envelop of my mini mill. It was not cheap though! But as I thought it would be useful I happily paid the money for it.

As I was new in milling I did not use the vice for months. A few times I tried to hold something and mill it in an angle I found it to be real difficult.

I blamed my lack of experience and let the vice on a self gathering dust.

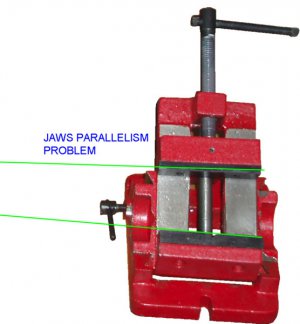

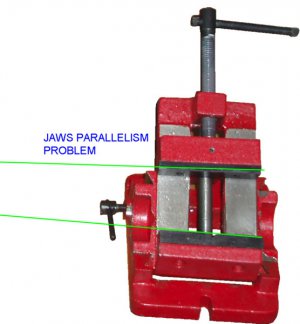

A few years later, having learn a few things more, I tried to mill a piece of aluminum in an angle of 45. I noticed that the vice had real problems in holding the piece. Jaws were not parallel!

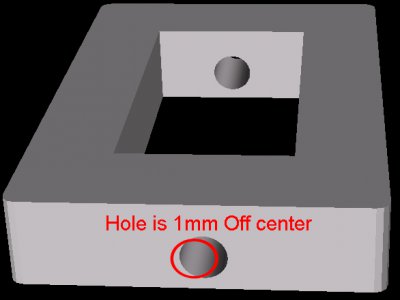

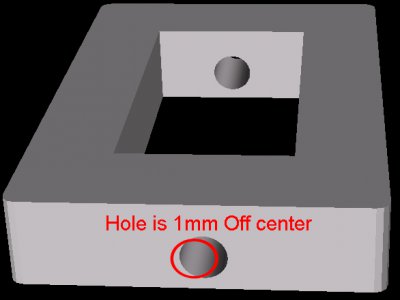

A classical Chinese quality control problem I thought. Seeking the cause of the problem I discovered that the moving jaw supporting rod was placed in a funny way! The supporting hole at the fix jaw side was off by 1 mm.

I was scratching my head for a solution to the problem as on the one hand, I did not wish to throw it away and, on the other, there is always a challenge to make something work as it should!!

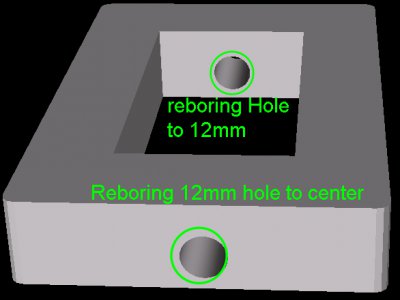

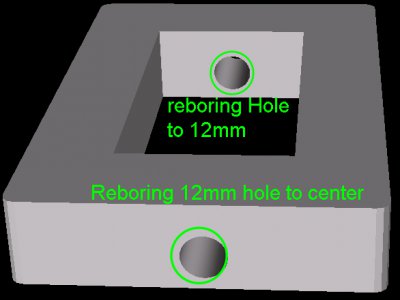

The only solution I thought, without major interventions to the vice body was to enlarge the holes by 2 mm as to center the problematic one and make a new supporting rod for it.

The easiest part was making the rod. I had raw material.

It was a matter of minutes to make it on the minilathe.

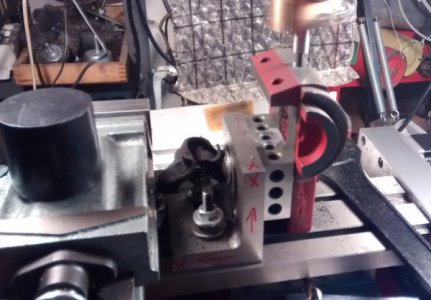

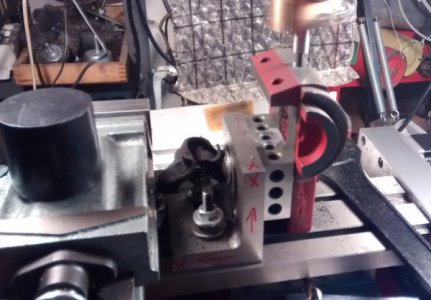

It was a challenge to properly secure the vice on the mill table, using an angle plate and a 1-2-3 block I worked it out

Reboring the correctly set hole was easy, but to find the exact offset to rebore the “wrongly placed” hole was a challenge. It took time and many trials to work it out!

Fitting the new rod to the vice was easy. Here is the back side.

And the front side

The new 12mm rod made it stronger in comparison to the old 10mm one

The vice works as it should now!

The only little thing I have to fix now is that the movable jaw, although perfectly parallel to the fix jaw, has been moved 1mm to the right.

Thanks for reading

Petros

One of them was a cast iron tilting machine vice.

Jaw opening, dimensions and the looks of it (I thought) was appropriate for the work envelop of my mini mill. It was not cheap though! But as I thought it would be useful I happily paid the money for it.

As I was new in milling I did not use the vice for months. A few times I tried to hold something and mill it in an angle I found it to be real difficult.

I blamed my lack of experience and let the vice on a self gathering dust.

A few years later, having learn a few things more, I tried to mill a piece of aluminum in an angle of 45. I noticed that the vice had real problems in holding the piece. Jaws were not parallel!

A classical Chinese quality control problem I thought. Seeking the cause of the problem I discovered that the moving jaw supporting rod was placed in a funny way! The supporting hole at the fix jaw side was off by 1 mm.

I was scratching my head for a solution to the problem as on the one hand, I did not wish to throw it away and, on the other, there is always a challenge to make something work as it should!!

The only solution I thought, without major interventions to the vice body was to enlarge the holes by 2 mm as to center the problematic one and make a new supporting rod for it.

The easiest part was making the rod. I had raw material.

It was a matter of minutes to make it on the minilathe.

It was a challenge to properly secure the vice on the mill table, using an angle plate and a 1-2-3 block I worked it out

Reboring the correctly set hole was easy, but to find the exact offset to rebore the “wrongly placed” hole was a challenge. It took time and many trials to work it out!

Fitting the new rod to the vice was easy. Here is the back side.

And the front side

The new 12mm rod made it stronger in comparison to the old 10mm one

The vice works as it should now!

The only little thing I have to fix now is that the movable jaw, although perfectly parallel to the fix jaw, has been moved 1mm to the right.

Thanks for reading

Petros