OK I took it apart, and it turns out it does matter. You have to turn the crank CCW to raise the head if it's upside-down like mine, vs. CW when assembled correctly. The following explanation is wordy and long and you can skip it unless interested.

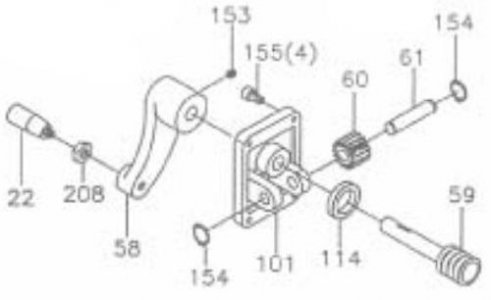

The rotation direction matters, because the helix on the #59 shaft (drawing abov in post #1) makes the shaft want to push out, away from the column, when you turn it CW, so the "head" on the shaft is bearing against the back of the casting #101 when you crank it up. This is good, the right place for it to rub (though I might put a thrust bearing there to reduce friction).

When you crank it CCW to raise the head, the shaft is forced inward toward the column, and the rubbing happens between the crank handle #58 and outside of the 101 casting. Not fatal, but the only thing keeping the 59 shaft from going too far in is the little setscrew in the handle, which can slip. This has been working OK for me for the year I've used it since I first assembled it wrong, but I did notice that when the head is all the way down and you keep cranking (an unusual scenario I know), the shaft comes outward a pretty far distance, 4 mm or so, indicating how far in the shaft has migrated due to the setscrew slipping. Sub-optimal, though I can't think of any catastophic problem it might cause.

If the forces were symmetric this wouldn't matter, cranking one way or the other would put the rubbing force on the inside or the outside of the 101 casting, but the big weight you're pushing against means the forces are always in one direction whether you're raising or lowering the head. Either direction you move the head (or even at rest), the weight is always taking out the slack in the #59 shaft in the same direction, and we want that direction to be outward.

Let's just say assembling it right has a small and somewhat theoretical advantage, but there's no advantage to doing it wrong. Words to live by!

I have ordered a needle thrust bearing to go between the head of the 59 shaft and the back of the 101 casting. I'll let you know when it arrives, whether it fits in the space available (I think so) and whether it makes a noticeable difference in cranking effort. On mine (and probably all similar machines), the friction is noticeable. The effort to raise the head is borderline for my old shoulders, which both need surgery. Maybe most of that effort is just the work of raising the mass, but I feel like the friction is making a substantial addition to the force needed. (Yes everything is lubed, in case you were wondering...) Even when I get my power lift installed, it's just going to be driven by a little hand drill, probably one of my cordless ones if it has the horsepower. Pretty sure it will, because I'm gearing it down a lot with sprocket sizes — it's chain-driven. It'll go up/down slowly, but I'm not in a hurry.