- Joined

- Dec 29, 2012

- Messages

- 394

1. Lifting heavy objects was never my strong point.

2. Dealing with machinery even for hobby, there is sometimes the need to lift heavy objects and the commercially available solutions do not fit the bill to do the job. Then, sometimes, you have to reinvent the wheel.

In my case having to lift heavy parts of a machine on my loft-shop I had to make an appropriate crane.

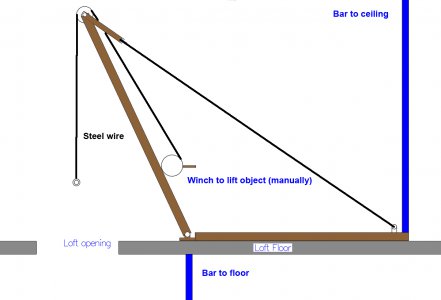

The initial idea was to keep it simple and, as it will be used only once or twice, to use material I already own.

I had enough pipes of several sizes and a manual winch from my boat trailer.

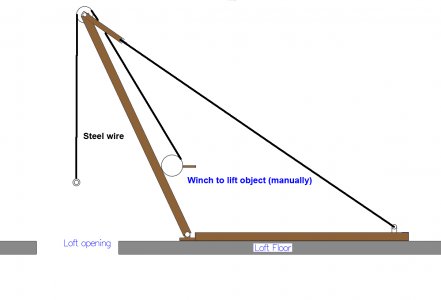

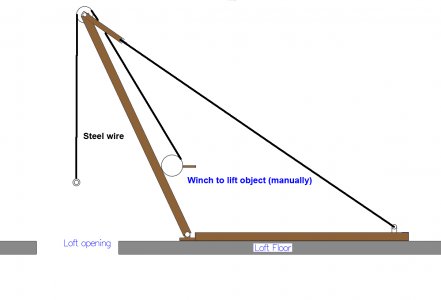

First plan was the following.

Ok! Before you start judging, I saw the problems from the beginning!

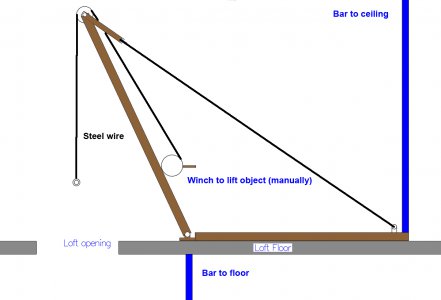

If I try to lift anything the crane will fall down as there is no support at the back. Some sort of support needed both on the back and under the boom.

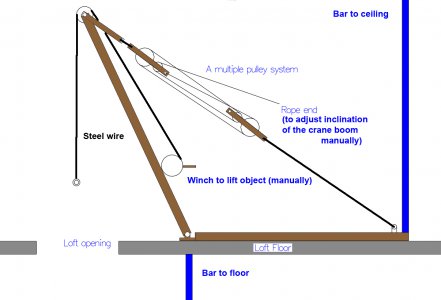

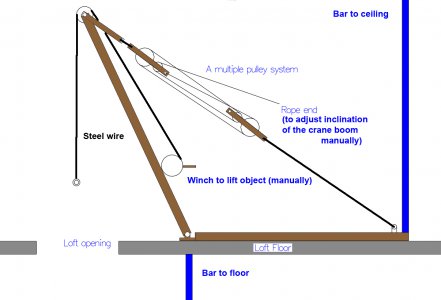

Feeling more confident now I needed a crane that not only lifts the weight through the opening, but it puts it on the loft. In other words near its boom base.

Feeling confident on the design I started cutting welding and testing the prototype on the garage that is the ground floor. My Loft-shop is exactly above it.

The crane needed to be modular as to make carrying and setting it easy.

Everything worked ok and I took it on the loft.

Needless to say that for the heavy machinery I reinforced the loft accordingly…

The crane took its position next to le loft opening (yes these are my feet!!).

Another view from above

View from below

Lifting works ok

As the part comes to the loft the boom is pulled back through the pulley system and the part sits safely on the loft.

So the lifting is fun to do!!

As the crane proved itself by lifting heavy machinery, I made a longer boom and used it to lift the new solar water heater from ground to theroof (4 floors up).

The support system is a little different though as I could not use a ceiling anymore and the pulley system was secured on a wall.

Thanks for reading

Petros

2. Dealing with machinery even for hobby, there is sometimes the need to lift heavy objects and the commercially available solutions do not fit the bill to do the job. Then, sometimes, you have to reinvent the wheel.

In my case having to lift heavy parts of a machine on my loft-shop I had to make an appropriate crane.

The initial idea was to keep it simple and, as it will be used only once or twice, to use material I already own.

I had enough pipes of several sizes and a manual winch from my boat trailer.

First plan was the following.

Ok! Before you start judging, I saw the problems from the beginning!

If I try to lift anything the crane will fall down as there is no support at the back. Some sort of support needed both on the back and under the boom.

Feeling more confident now I needed a crane that not only lifts the weight through the opening, but it puts it on the loft. In other words near its boom base.

Feeling confident on the design I started cutting welding and testing the prototype on the garage that is the ground floor. My Loft-shop is exactly above it.

The crane needed to be modular as to make carrying and setting it easy.

Everything worked ok and I took it on the loft.

Needless to say that for the heavy machinery I reinforced the loft accordingly…

The crane took its position next to le loft opening (yes these are my feet!!).

Another view from above

View from below

Lifting works ok

As the part comes to the loft the boom is pulled back through the pulley system and the part sits safely on the loft.

So the lifting is fun to do!!

As the crane proved itself by lifting heavy machinery, I made a longer boom and used it to lift the new solar water heater from ground to theroof (4 floors up).

The support system is a little different though as I could not use a ceiling anymore and the pulley system was secured on a wall.

Thanks for reading

Petros

Last edited: