- Joined

- Dec 29, 2012

- Messages

- 394

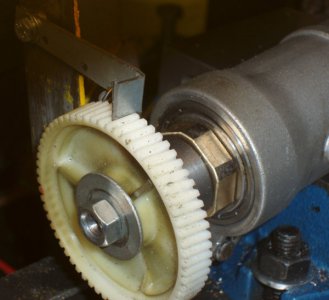

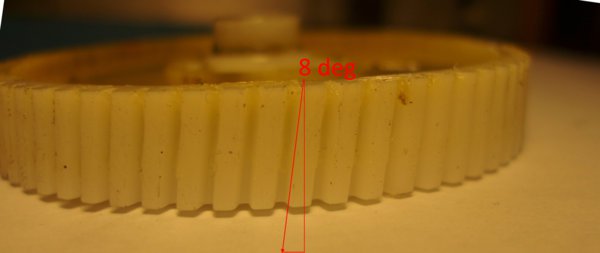

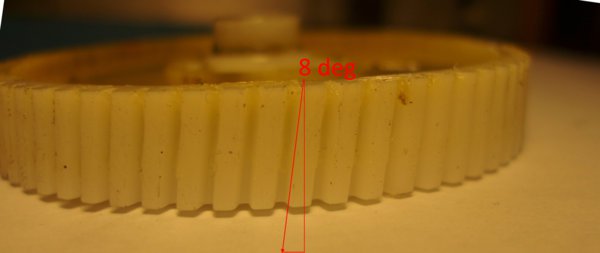

I needed to cut a useable worm gear for a car door (window) mechanism

The motor and the enclosure of the mechanism are pretty solid but the plastic gear gave up making it useless.

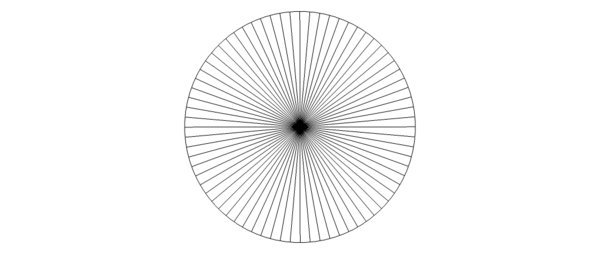

I intent to use it for a new project and I need a new metal worm gear to replace the plastic one. To machine it I need a simple dividing head which I do not own! To solve the problem I made a simple dividing head that uses gears as the index. Thus, the number of teeth on the back gives you the same number at the front.

To expand the indexing range I intent to use all gears provided by my mini lathe. My minilathe has a wide range of gears (20, 30, 35, 40, 45, 50, 55, 57, 60, 65, 80) so I can cut gears with a variety of teeth: 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 15, 19, 20, 25, 30, 35, 40, 45, 50, 55, 57, 6 0, 65, 80.

First lets see what car industry offers ready made for that job!

Yes! That is a motor assisted steering wheel column.

It offers a section that is very convenient for the job.

After machining the shaft at steering wheel end, I made it support 8mm and 12 mm (mini lathe) indexing gears.

I also made a 20x1mm large nut to secure the shaft to the indexer body.

An adaptor to support 8mm hole gears

A thick washer to secure 12 mm gears

I machined a 55cm recess at the other end of the shaft to fit a 3” chuck

And welded 3 steel extensions at the back of the shaft plate to secure the chuck in place

Dividing head ready!

All I need now is an index finger stop. Something simple…

Made using a few angle bars and a spring

Now I can copy this peculiar plastic worm gear to a bronze one.

I secured the indexer to the mill vice at 8deg angle.

Chose the appropriate gear cutter 0.5mod, 20 deg. #8 (>135 teeth)

Prepared the bronze blank on the lathe

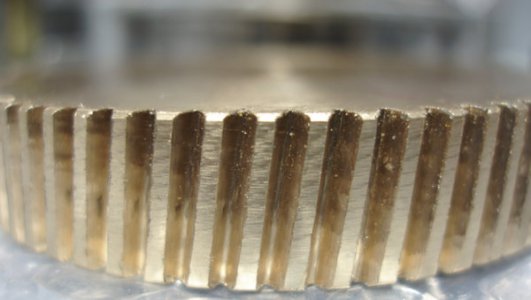

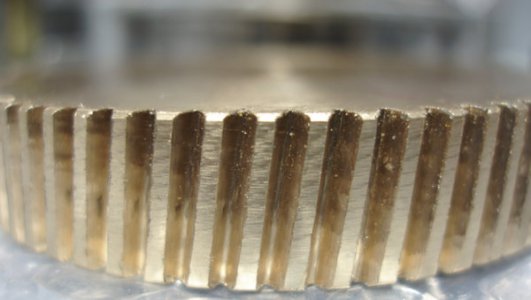

And cut the gear

It looks nice

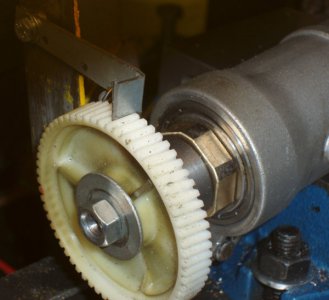

Fits nicely

And works nicely

Thanks for reading

Petros

The motor and the enclosure of the mechanism are pretty solid but the plastic gear gave up making it useless.

I intent to use it for a new project and I need a new metal worm gear to replace the plastic one. To machine it I need a simple dividing head which I do not own! To solve the problem I made a simple dividing head that uses gears as the index. Thus, the number of teeth on the back gives you the same number at the front.

To expand the indexing range I intent to use all gears provided by my mini lathe. My minilathe has a wide range of gears (20, 30, 35, 40, 45, 50, 55, 57, 60, 65, 80) so I can cut gears with a variety of teeth: 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 15, 19, 20, 25, 30, 35, 40, 45, 50, 55, 57, 6 0, 65, 80.

First lets see what car industry offers ready made for that job!

Yes! That is a motor assisted steering wheel column.

It offers a section that is very convenient for the job.

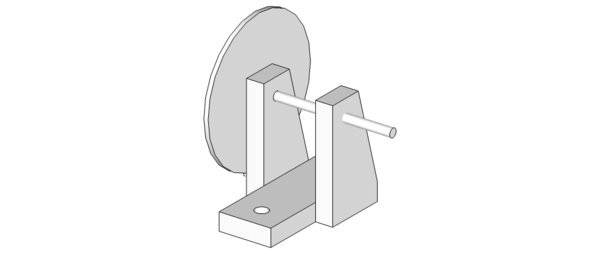

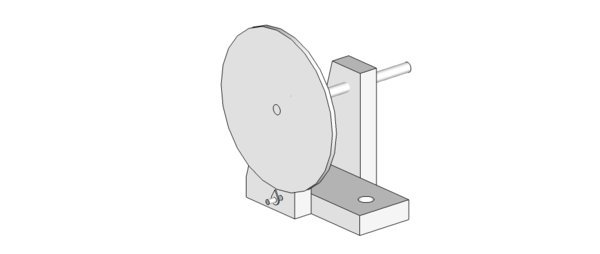

After machining the shaft at steering wheel end, I made it support 8mm and 12 mm (mini lathe) indexing gears.

I also made a 20x1mm large nut to secure the shaft to the indexer body.

An adaptor to support 8mm hole gears

A thick washer to secure 12 mm gears

I machined a 55cm recess at the other end of the shaft to fit a 3” chuck

And welded 3 steel extensions at the back of the shaft plate to secure the chuck in place

Dividing head ready!

All I need now is an index finger stop. Something simple…

Made using a few angle bars and a spring

Now I can copy this peculiar plastic worm gear to a bronze one.

I secured the indexer to the mill vice at 8deg angle.

Chose the appropriate gear cutter 0.5mod, 20 deg. #8 (>135 teeth)

Prepared the bronze blank on the lathe

And cut the gear

It looks nice

Fits nicely

And works nicely

Thanks for reading

Petros