- Joined

- Dec 9, 2016

- Messages

- 3

I am glad to find someone who has a KA-200 scale in hand and can probably answer my question.The Sino KA-200 slim scales are the smallest glass scales i've seen - 16mm x 16mm. The only thing to becareful about is that they come in 1um and 5um and of course i ordered the 5um by mistake!

Subscribed and watching to see how the new scales fit your machine.

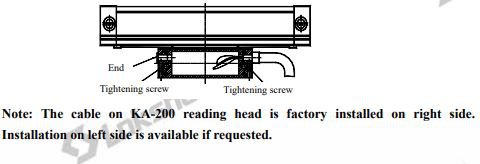

I am in the process of adding a DRO to my South Bend 10K lathe and this scale is the only 1um glass scale small enough to use on the cross slide. In reviewing available information I find this statement in the SINO Linear Scale Installation Guide ---- "The cable on the KA-200 reading head is factory installed on the right side. Installation on the left side is available if requested." Every photo on line shows the cable on the right side and this statement leads me to believe that the scale can only be installed with the back side against the machine it's installed on. My installation will require the cable to be on the left side so I emailed the sellers on eBay and AliExpress to ask if they could provide same. They responded that I can just install it with the front side against the machine but I am reluctant to take the risk so I emailed SINO with the question of where can I get one with the cable on the left but have not received any response after a week.

So I am hoping you can answer the question -- "Is there something about the KA-200 that would prevent it being installed the other way around with the cable exiting to the left?"

Thank You for your time!