- Joined

- May 16, 2016

- Messages

- 194

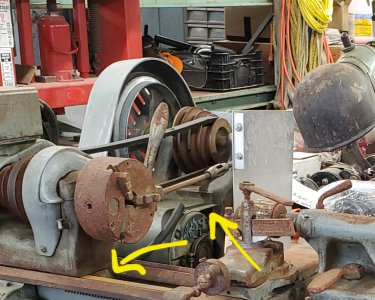

When I was rebuilding my 9B, I ran myself in circles trying to figure out the headstock to bed mounts, and where I put them. Came to realize that the '47 model was the one year to not use these, and the ones I found to "replace" the missing ones not only wouldn't do anything, but were just wasted money. Of course, the manuals I found online did not let me in on this.

All of which to say, be careful when rebuilding these lathes. They were made for a long time, and there are many small variations due to production needs and former owners.

All of which to say, be careful when rebuilding these lathes. They were made for a long time, and there are many small variations due to production needs and former owners.