- Joined

- Jan 20, 2013

- Messages

- 272

I've made a bunch of tooling, but this is one of my favorites.

This is a wrench for the mill spindle on my machine.

Before I made this, I had one heck of a time tightening and loosening the draw bar on my mill!

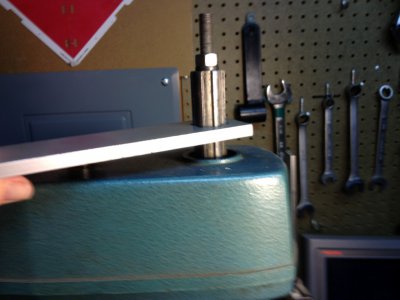

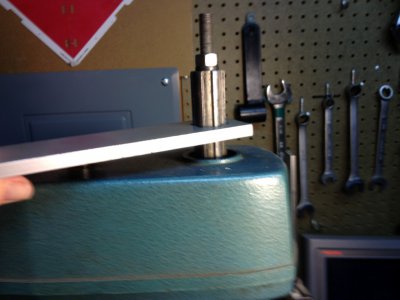

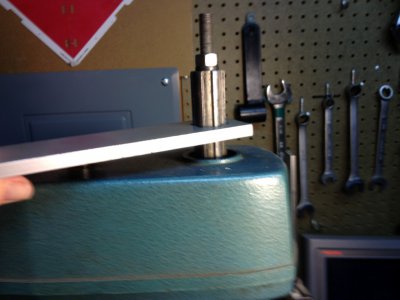

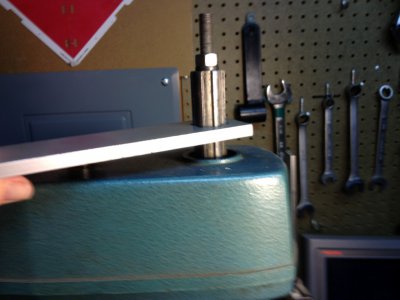

I simply measured the minor diameter of the outside of the spindle and measured the width of the splines on the spindle. Then I used my rotary table to drill six holes the diameter of the width of the splines, through a piece of 3/8 thick aluminum bar, a hair bigger than the pitch of the minor diameter of the spindle. Today I would use the bolt circle calculator of my DRO. Then I just drilled and bored out the center to just slightly larger than the minor diameter of the spindle.

Here is the wrench in action. This is a Godsend IMO. Notice my hand is on it. I try not to ever take my hand off it when on the spindle. Why? because this thing would be lethal if I ever forgot it was there and turned the machine on. So, I take it off the pegboard behind the machine, tighten or loosen the draw bar, and then return it to the pegboard without ever letting go of it.

Later, I even made good use of the other end of the wrench. I made a spanner for the 5C collet fixture that I scored for the quick change tool post for my lathe.

So this is certainly not an elegant or sophisticated tool, but it is worth it's weight in gold to me. I use it all the time.

Thanks for checking it out, let me know what you think!

Best regards,

Dave

This is a wrench for the mill spindle on my machine.

Before I made this, I had one heck of a time tightening and loosening the draw bar on my mill!

I simply measured the minor diameter of the outside of the spindle and measured the width of the splines on the spindle. Then I used my rotary table to drill six holes the diameter of the width of the splines, through a piece of 3/8 thick aluminum bar, a hair bigger than the pitch of the minor diameter of the spindle. Today I would use the bolt circle calculator of my DRO. Then I just drilled and bored out the center to just slightly larger than the minor diameter of the spindle.

Here is the wrench in action. This is a Godsend IMO. Notice my hand is on it. I try not to ever take my hand off it when on the spindle. Why? because this thing would be lethal if I ever forgot it was there and turned the machine on. So, I take it off the pegboard behind the machine, tighten or loosen the draw bar, and then return it to the pegboard without ever letting go of it.

Later, I even made good use of the other end of the wrench. I made a spanner for the 5C collet fixture that I scored for the quick change tool post for my lathe.

So this is certainly not an elegant or sophisticated tool, but it is worth it's weight in gold to me. I use it all the time.

Thanks for checking it out, let me know what you think!

Best regards,

Dave

Last edited: