- Joined

- Sep 28, 2013

- Messages

- 4,318

I needed a 2nd chuck key for my 4 jaw so I figured I'd use my new collet chuck (http://www.hobby-machinist.com/threads/er25-collet-chuck-for-atlas-618.41636/) to make one  I got my inspiration from a tap handle I was fiddling with - this way I can move the handle around for clearance or leverage.

I got my inspiration from a tap handle I was fiddling with - this way I can move the handle around for clearance or leverage.

stock - random printer bars I think

back end of the key faced and beveled

drilled about an inch deep with a #30 drill, as I was going to use 1/8 brass stock for the button

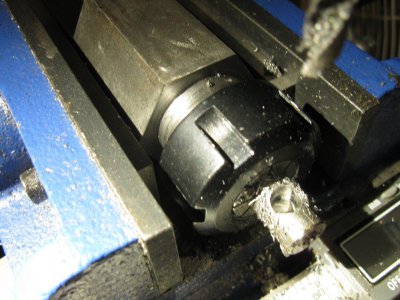

1/8 brass stock in a 3mm collet - it was then turned down to fit inside the spring and parted off

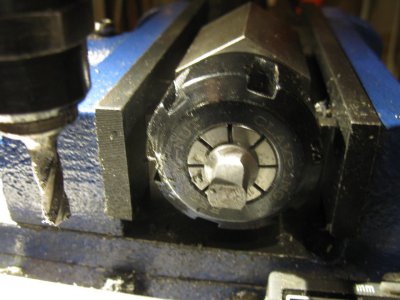

turned round, put in a 2mm collet (love this chuck!) and faced

ta da!

end of the chuck key body turned down to what I thought was the right size, turned out a bit small so the edges won't be bevelled

stock - random printer bars I think

back end of the key faced and beveled

drilled about an inch deep with a #30 drill, as I was going to use 1/8 brass stock for the button

1/8 brass stock in a 3mm collet - it was then turned down to fit inside the spring and parted off

turned round, put in a 2mm collet (love this chuck!) and faced

ta da!

end of the chuck key body turned down to what I thought was the right size, turned out a bit small so the edges won't be bevelled