Here is the contents of Jcl's word document. The pictures might have been re-sized. I posted each as a screen capture. Let's hope it works.

Steve

Jake,

I would not call your interesting lathe “Frankenstein’s Monster”, possibly Rosemary’s baby, but hardly a monster. It has more historical than practical value, but it is still functional and usable for certain operations, especially for watchmakers. With later pictures you have posted I see how the slide rest is attached to your lathe. There has been some skillful work adapting a slide with a T slot to a square mount on your lathe. I have no idea when that was done, but it is an adaptation I believe, without seeing all of this first hand, you understand.

I said I would show some pictures of both ancestors and descendants of your lathe. This will be my first attempt to post pictures to this list. Let’s see what happens:

The first picture is of a 19th C. Swiss turns. I have shown it with a bow resting against it. This one has unusual runners because the center on he right runner is off center, and the other has what looks like a triangle on its end. This turns was for especially delicate watch arbors, and each corner of the triangle had a different size hole to fit a different size pivot on a watch wheel.

View attachment 127065

As I explained in an earlier post, a tiny pulley would be attached to the work, the horse hair or, here, fish line was wrapped around the pulley so that the work rotated forward then back. Part of the skill was to match the rhythm of the bow with the action applied to the work.

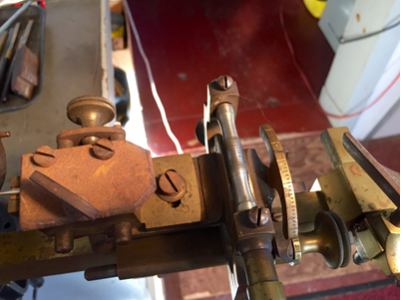

The next picture is a nearly traditional Swiss Mandrel lathe. A watch plate would be mounted to the face plate, and the slide rest or a hand-held graver resting on the T rest could make a recess on the plate, or bore a hole for a jewel or bearing. The late Ted Crom, who was an authority on early watchmaker’s tools, said that the lathe in this picture is the only one he ever saw where the slide rest used a sector of a worm wheel instead of a flat slide as a cross slide. Some mandrel lathes came equipped with a tailstock, but so few have them that it is reasonable to assume that the tailstock would be an extra attachment. A tailstock would actually be of little use on a mandrel lathe.

View attachment 127066

View attachment 127067

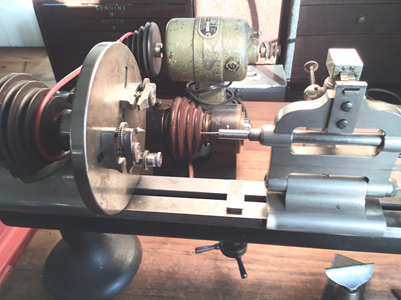

Below you see a modern faceplate headstock for a watchmaker’s lathe. The face plate is permanently attached to a dedicated headstock; it cannot be removed. Consequently it’s accuracy cannot be disturbed (except by an accident). It is used the same way a Swiss mandrel lathe would be used. Also mounted on the lathe bed is what is called a jewelling tailstock. Simply explained, because the spindle that would hold a boring tool is half the distance from the hinge at the base of the tool, to a table seen at the top of the tool, a watch jewel could be set on that table, and the boring tool would open a hole in a watch plate the right diameter for the jewel to be fitted into the watch plate. At half the distance from hinge to table the boring bar was cutting half the diameter of the jewel: the radius. You may have to think about the device for a minute, and its effectiveness does depended entirely on having the tool carefully adjusted.

View attachment 127068

Finally, below is an image of an 18th C. English “Throw.” It is more common to clockmakers than watchmakers but it was used by both. Think of it as a very early bench lathe. The image shown is courtesy of the Willard House and Clock Museum, Grafton, Mass. where there is an extensive collection of early horological tools. As with the turns, most work was done between centers, usually with tools resting on a T rest. Note the wear on the T rest. This tool seems to have some mileage on it. In the lower left of that picture I notice you can see the right side of an English turns. It was not as elegant as the Swiss turns of the same era, but equally functional.

View attachment 127069

This response is long, and I apologize for some of the bad pictures, taken “last minute”, but I hope it is helpful. Jcl