- Joined

- Oct 5, 2021

- Messages

- 16

Hi guys, I believe this is my first thread I've started and maybe my 4th or 5 post (maybe). So its going to be a long one, So be prepared. LoL

So in 2016 I suffered a life changing accident that wasn't my fault. And at 46 yrs old and being a Heavy Equipment operator and A very accomplished truck driver thats hauled this big iron Equipment for going on 25 yrs at the time. Life was going along pretty well till that faithful day in late January. When I got hit by a distracted driver. And the injuries some 5 yrs later have basically taken 90% use of my left arm and severe nerve damage to the arm and left hand. Thus taking me out of the work force and forced into medical retirement. Being a Firearms enthusiasts and a recreational shooter, Working on Firearms (And now building my own) has always been a passion (And a goal) of mine. So first came a Darsin 1440 lathe. Then a Grizzly 1006/1007 Drill Mill. There "Might" Have even been a Central Machine lathe Drill combo that "Could have " been brought home and cleaned up and sold. But all photographic evidence of that has been destroyed, Im sure of that. LoL

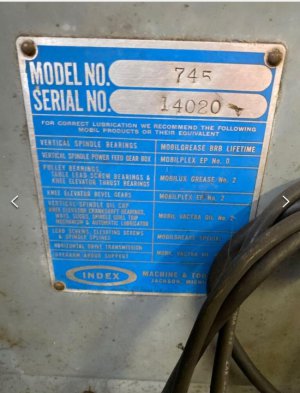

So after playing around with the Grizzly a bit. And realizing pretty quickly thats its a fare better drill press than a actually mill. I started looking for a actually "Vertical Mill" I was finding a lot of older Bridgeports that seemed to still have some life left in them for a guy to play around in his Home Shop/Gargage. So after driving all over NE Ohio and kick a lot of tires and seeing some pretty clapped out junk that problem needed to be in the scrap yard (So said my Machinest buddy of 35 yrs) I continued my search, Learning along the way of what and where to look for "Acceptable wear" Then in late November I found a listing in a Auction near by for a "Wells Index 745" And the photos looked decent. So the day of preview for this Online Only Auction I went and gave her a peek. Still wired and under power showed that all the motors worked. But there was a thick layer of what I can on describe as cosmoline type grease all over the machine. And not wanting to force anything, I quickly realized what the other potential biders where shaking there heads at and calling it "Frozen up" Wasn't necessarily accurate. So after waiting around till the gentleman that was showing the Auction items was ready to close up the building that had not had heat or AC in 29 yrs. Since the shop closed in March of 1992. I then started trying to see if the controls where actually frozen up or just locked in this dark hard (at one time semi liquid) maple surp looking yuck that was on the machine from top to bottom. Then the Grandson of the deceased owner and his deceased father approached me and told me the story of the building and the business. And how after his grandfathers unexpected death in March of 1992 the shop closed. And his dad never had the heart to reopen it. And after his death in 2010. He and his sister have been the sole owner ever since. And that the building sat on 38 acres of Commercial property. And the building was in extremely poor shape. So they had a more than fare offer to sell it to a commercial builder that need a piece of land for a local company to expand on at least half of the land. Bringing the likely hood of 70-90 employees to the area. So he sold it. Saying its what his grandfather would have wanted, "He believed in jobs making American made products" And that all the machines had been sprayed down with this protective coating by his father when the shop closed Not knowing how long it would be till he could re-open it.

So at the end of the auction I picked up this 745 for what I believe (and have been told) for scrap price. All in, Just under $600.00. So getting it home seemed to be the uneventful deal. Until the 3 of us contracted Covid 19 from someone there the day of removal. As did several others and the complete Auction company employees. O'well, What are you going to?? It is what it is.

So we get her home, Contracting a local towing company with there single axle roll back wrecker was the best idea I've had in a long time. And well worth the $200.00 (cash) for the loading and transportation. So after recovering from C-19, Actually doing while stuck at home in quarantine. I started the process of removing 30 yrs of sitting and not moving at all. And to my surprise, Mean Green lossened up a lot of it. And what that didn't, Mineral Spirits in a air pressurized spray can did.

We where able to lower the knee and to rotate the head to get it as compact as possible for transportation. Next was the arm the heads on. It loosened, And moved in and out as it should,Great. Next was the power feed gear box, The levers where NOT going to be team players. And when I attempted to drain the oil out, It looked more like grease on a cold day trying to leave the only home its had in 30 yrs, Not pretty. Even after 10 hours of a heater blowing on it. It still wasn't looking good.

So about this time Mark from Wells Index returns my call and tells me that this machine was sold New in February of 1968 to the company and location that I bought it from. And that they did the first service and adjustments after break in about 4 months after it went into service.

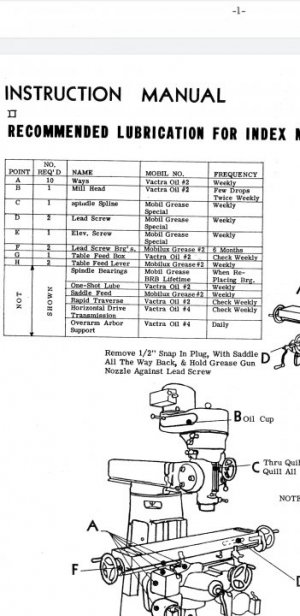

So figuring there was a decent chance that the gear oil in that box as likely original. And after we ran a bore camera in to it and looked around. I decided I better pull the box off and clean it and all of its shafts and gears and bearings up the right way. And aim I glad I did. Because as things came apart. I quickly discovered that all the bearings that had grease in them, It had become as hard as candle wax. And all dried out over 30 yrs of sitting. And the bearings in the sides of the box that where lubed by the gear oil had what we found out later was rust where the oil had run out and over 30 yrs been pitted pretty good. The gears and the shafts where so sticky you put a gear in your hand and turn it over and it wouldn't fall off your hand. So after a good bath and inspection. We found some numbers for my bearings guy to chew on. And after some "Moaning and Growning" He always does that. He got me all the bearings we needed to put the power feed back together. Before we did this we pulled the table off and cleaned and inspected everything there. No major cuts or gouges and no major wear where found. So since we where that fare into this,We did the same on the saddle. Other than the gibs where way over tightened. And as my Machinest buddy said, "That was a common practice back in the day: Especially if you where not moving the Y axis. much and had the machine on a delicated job. So again we cleaned and inspected and found the bearings in there to be packed completely full of grease that wasn't as dried out as the rest had been. Probably because this machine was fitted with grease fittings at the hand controls. And also was fitted with a one pump daily ways oil system. So after cleaning these bearings up in the parts washer. And repacking them with the expensive as hell Mobil synthetic grease that Wells recommends and uses when they do a rebuild. She was ready to go back together. While we where inspecting, I noticed that the wipers where pretty hard and even had some cracks in them. So another call to Wells and they sent me what looked like about 24" (enough to do the whole machine) That was like $30.00 or so. So after putting those in last night. Note, A 3rd hand THAT WORKS would have been very helpful for that job. Im sure using some spray on glue to kelp keep them in place, once you cut them to fit. Definitely would have been a better idea. But I managed to get them all in and they look and work just like new.

So the next obstacle is removing the Quill. Unfortunately this mill was sold with the old B&S #9 ground quill. And after doing my research and looking for those tool holders, Its going back to Wells Index and going to be ground for the more common R-9 tool holders. Which i have acquired a decent collection over the last few months of attending auctions looking for "Previously enjoyed " tooling. The cost to Re-Grind the quill is actually more than I paid for the mill it self. But there just isn't a lot of B&S #9 to be had from what I can find. And the tooling that was at the auction where this came from looked as if the wind blew rain and snow threw a broken window somewhere in 30 yrs and everything in that box was so rusted and pitted. That it wasn't worth even trying to save the 10 that where there.

So as there doing that job, ill be wiring up the New American Rotary AR-5 Phase Converter. So when the quill returns from its trip to Michigan. Will be all set to make chips. So if you're still with me to this point. And YES I did all this on my phone key board (SMH). We checked the bearings in the head. And since they where lubed by the ways oil in the cup on the head, And not full of the dried out wax grease. They are good to go. All after we gave them a good healthy well deserved drink of new clean ways oil. Photo is prior to starting the cleaning and work. I'll have to add some current ones on the next (shorter, I promise) post.

So in 2016 I suffered a life changing accident that wasn't my fault. And at 46 yrs old and being a Heavy Equipment operator and A very accomplished truck driver thats hauled this big iron Equipment for going on 25 yrs at the time. Life was going along pretty well till that faithful day in late January. When I got hit by a distracted driver. And the injuries some 5 yrs later have basically taken 90% use of my left arm and severe nerve damage to the arm and left hand. Thus taking me out of the work force and forced into medical retirement. Being a Firearms enthusiasts and a recreational shooter, Working on Firearms (And now building my own) has always been a passion (And a goal) of mine. So first came a Darsin 1440 lathe. Then a Grizzly 1006/1007 Drill Mill. There "Might" Have even been a Central Machine lathe Drill combo that "Could have " been brought home and cleaned up and sold. But all photographic evidence of that has been destroyed, Im sure of that. LoL

So after playing around with the Grizzly a bit. And realizing pretty quickly thats its a fare better drill press than a actually mill. I started looking for a actually "Vertical Mill" I was finding a lot of older Bridgeports that seemed to still have some life left in them for a guy to play around in his Home Shop/Gargage. So after driving all over NE Ohio and kick a lot of tires and seeing some pretty clapped out junk that problem needed to be in the scrap yard (So said my Machinest buddy of 35 yrs) I continued my search, Learning along the way of what and where to look for "Acceptable wear" Then in late November I found a listing in a Auction near by for a "Wells Index 745" And the photos looked decent. So the day of preview for this Online Only Auction I went and gave her a peek. Still wired and under power showed that all the motors worked. But there was a thick layer of what I can on describe as cosmoline type grease all over the machine. And not wanting to force anything, I quickly realized what the other potential biders where shaking there heads at and calling it "Frozen up" Wasn't necessarily accurate. So after waiting around till the gentleman that was showing the Auction items was ready to close up the building that had not had heat or AC in 29 yrs. Since the shop closed in March of 1992. I then started trying to see if the controls where actually frozen up or just locked in this dark hard (at one time semi liquid) maple surp looking yuck that was on the machine from top to bottom. Then the Grandson of the deceased owner and his deceased father approached me and told me the story of the building and the business. And how after his grandfathers unexpected death in March of 1992 the shop closed. And his dad never had the heart to reopen it. And after his death in 2010. He and his sister have been the sole owner ever since. And that the building sat on 38 acres of Commercial property. And the building was in extremely poor shape. So they had a more than fare offer to sell it to a commercial builder that need a piece of land for a local company to expand on at least half of the land. Bringing the likely hood of 70-90 employees to the area. So he sold it. Saying its what his grandfather would have wanted, "He believed in jobs making American made products" And that all the machines had been sprayed down with this protective coating by his father when the shop closed Not knowing how long it would be till he could re-open it.

So at the end of the auction I picked up this 745 for what I believe (and have been told) for scrap price. All in, Just under $600.00. So getting it home seemed to be the uneventful deal. Until the 3 of us contracted Covid 19 from someone there the day of removal. As did several others and the complete Auction company employees. O'well, What are you going to?? It is what it is.

So we get her home, Contracting a local towing company with there single axle roll back wrecker was the best idea I've had in a long time. And well worth the $200.00 (cash) for the loading and transportation. So after recovering from C-19, Actually doing while stuck at home in quarantine. I started the process of removing 30 yrs of sitting and not moving at all. And to my surprise, Mean Green lossened up a lot of it. And what that didn't, Mineral Spirits in a air pressurized spray can did.

We where able to lower the knee and to rotate the head to get it as compact as possible for transportation. Next was the arm the heads on. It loosened, And moved in and out as it should,Great. Next was the power feed gear box, The levers where NOT going to be team players. And when I attempted to drain the oil out, It looked more like grease on a cold day trying to leave the only home its had in 30 yrs, Not pretty. Even after 10 hours of a heater blowing on it. It still wasn't looking good.

So about this time Mark from Wells Index returns my call and tells me that this machine was sold New in February of 1968 to the company and location that I bought it from. And that they did the first service and adjustments after break in about 4 months after it went into service.

So figuring there was a decent chance that the gear oil in that box as likely original. And after we ran a bore camera in to it and looked around. I decided I better pull the box off and clean it and all of its shafts and gears and bearings up the right way. And aim I glad I did. Because as things came apart. I quickly discovered that all the bearings that had grease in them, It had become as hard as candle wax. And all dried out over 30 yrs of sitting. And the bearings in the sides of the box that where lubed by the gear oil had what we found out later was rust where the oil had run out and over 30 yrs been pitted pretty good. The gears and the shafts where so sticky you put a gear in your hand and turn it over and it wouldn't fall off your hand. So after a good bath and inspection. We found some numbers for my bearings guy to chew on. And after some "Moaning and Growning" He always does that. He got me all the bearings we needed to put the power feed back together. Before we did this we pulled the table off and cleaned and inspected everything there. No major cuts or gouges and no major wear where found. So since we where that fare into this,We did the same on the saddle. Other than the gibs where way over tightened. And as my Machinest buddy said, "That was a common practice back in the day: Especially if you where not moving the Y axis. much and had the machine on a delicated job. So again we cleaned and inspected and found the bearings in there to be packed completely full of grease that wasn't as dried out as the rest had been. Probably because this machine was fitted with grease fittings at the hand controls. And also was fitted with a one pump daily ways oil system. So after cleaning these bearings up in the parts washer. And repacking them with the expensive as hell Mobil synthetic grease that Wells recommends and uses when they do a rebuild. She was ready to go back together. While we where inspecting, I noticed that the wipers where pretty hard and even had some cracks in them. So another call to Wells and they sent me what looked like about 24" (enough to do the whole machine) That was like $30.00 or so. So after putting those in last night. Note, A 3rd hand THAT WORKS would have been very helpful for that job. Im sure using some spray on glue to kelp keep them in place, once you cut them to fit. Definitely would have been a better idea. But I managed to get them all in and they look and work just like new.

So the next obstacle is removing the Quill. Unfortunately this mill was sold with the old B&S #9 ground quill. And after doing my research and looking for those tool holders, Its going back to Wells Index and going to be ground for the more common R-9 tool holders. Which i have acquired a decent collection over the last few months of attending auctions looking for "Previously enjoyed " tooling. The cost to Re-Grind the quill is actually more than I paid for the mill it self. But there just isn't a lot of B&S #9 to be had from what I can find. And the tooling that was at the auction where this came from looked as if the wind blew rain and snow threw a broken window somewhere in 30 yrs and everything in that box was so rusted and pitted. That it wasn't worth even trying to save the 10 that where there.

So as there doing that job, ill be wiring up the New American Rotary AR-5 Phase Converter. So when the quill returns from its trip to Michigan. Will be all set to make chips. So if you're still with me to this point. And YES I did all this on my phone key board (SMH). We checked the bearings in the head. And since they where lubed by the ways oil in the cup on the head, And not full of the dried out wax grease. They are good to go. All after we gave them a good healthy well deserved drink of new clean ways oil. Photo is prior to starting the cleaning and work. I'll have to add some current ones on the next (shorter, I promise) post.

Attachments

Last edited: