-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Threaded on 12" 3 jaw removal

- Thread starter Batmanacw

- Start date

- Joined

- Dec 24, 2020

- Messages

- 1,192

You said the board in the pulley isn't tight and that you can wiggle the 2x4 by hand. It looks like a 4x4 rather than a 2x4, but if it's loose enough you can wiggle it by hand with all that weight on the wrench something doesn't make sense.Uh.....the floor......

A little propane torch isn't going to put enough heat into all that cast iron to make any difference. Taking the chuck off so it's just the mass of the backing plate soaking up the heat might help...doubtful, but won't hurt.

Went through many of the same ideas here:

Turn Off Lathe Backing Plate...Tips?

I went to remove the chuck from my Sheldon lathe (13 x 36) which has a 2-1/4 - 8 thread-on chuck and it's stuck...I mean really stuck. I haven't been using this particular lathe long and haven't removed the chuck previously. I had the exact same model lathe, minus a taper attachment...

www.hobby-machinist.com

www.hobby-machinist.com

I am not busting teeth off my gears like that.Maybe a 2 x 4 against a jaw, hit with 5 lb hammer? Cant ruin a rotten egg.

You said the board in the pulley isn't tight and that you can wiggle the 2x4 by hand. It looks like a 4x4 rather than a 2x4, but if it's loose enough you can wiggle it by hand with all that weight on the wrench something doesn't make sense.

A little propane torch isn't going to put enough heat into all that cast iron to make any difference. Taking the chuck off so it's just the mass of the backing plate soaking up the heat might help...doubtful, but won't hurt.

Went through many of the same ideas here:

Turn Off Lathe Backing Plate...Tips?

I went to remove the chuck from my Sheldon lathe (13 x 36) which has a 2-1/4 - 8 thread-on chuck and it's stuck...I mean really stuck. I haven't been using this particular lathe long and haven't removed the chuck previously. I had the exact same model lathe, minus a taper attachment...www.hobby-machinist.com

Gear reduction is a thing. The lathe is set for 14 rpm. The pulley runs at 1150 rpm to achieve 14 rpm. The weight on that pulley is significantly less than the weight on the chuck. The pulley cannot turn but it is in no danger of breaking.

My crappy little propane torch got the chuck hot enough to boil out some of the grease in the chuck. It started to vaporize some of the penetrating oil in the threads. It's just not hot enough fast enough.

- Joined

- Nov 25, 2015

- Messages

- 9,594

Just a piece of hex?There is nothing for me to grab in the chuck that I can put 1000 ft lbs on. Then I cannot access the bore.

That jaw is over 1.25" thick of solid cast iron. It isn't moving or bending or twisting or deforming.

A collet block?

Just a piece of hex?

A collet block?

I might have 1/2" hex stock. Considering 1000 ft lbs of torque isn't doing much, I can say that anything I have to chuck up is going to be useless. The wrench on the jaw is 1 5/16". A 2" hex in the chuck would put the torque on the wrench up to 1000 ft lbs instead of a lower amount of force at the perimeter of the chuck.

- Joined

- Dec 24, 2020

- Messages

- 1,192

I know gear reduction is a thing, I just wasn't sure what you were saying.Gear reduction is a thing. The lathe is set for 14 rpm. The pulley runs at 1150 rpm to achieve 14 rpm. The weight on that pulley is significantly less than the weight on the chuck. The pulley cannot turn but it is in no danger of breaking.

My crappy little propane torch got the chuck hot enough to boil out some of the grease in the chuck. It started to vaporize some of the penetrating oil in the threads. It's just not hot enough fast enough.

That's what I was suggesting about propane. I don't think even a propane cutting torch would be able to put enough heat into something that large to get it hot enough to help. I tried a large oxyacetylene setup and even that didn't do it.

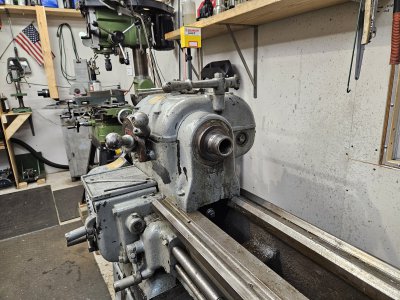

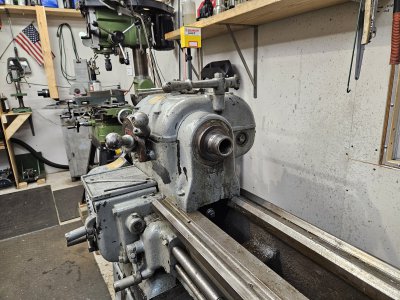

This is what victory looks like!

This is how much heat a Bernzomatic can put out over time.

So relieved. The face of the spindle where the backing plate contacts needs to be lightly trued. It is slightly mushroomed.

My Fairmount wrench is now a 1 3/8" opening to 1 7/16". I'll have to buy a new 1 5/16" to replace it. Lol.

I ended up pinching a 4x6 under one of the jaws stuck out about half way. Then I put a prybar into the pulley and used the gear reduction to finally break it loose.

This is how much heat a Bernzomatic can put out over time.

So relieved. The face of the spindle where the backing plate contacts needs to be lightly trued. It is slightly mushroomed.

My Fairmount wrench is now a 1 3/8" opening to 1 7/16". I'll have to buy a new 1 5/16" to replace it. Lol.

I ended up pinching a 4x6 under one of the jaws stuck out about half way. Then I put a prybar into the pulley and used the gear reduction to finally break it loose.

- Joined

- Jan 2, 2019

- Messages

- 7,115

Knew you would get itThis is what victory looks like!

View attachment 483723

This is how much heat a Bernzomatic can put out over time.

View attachment 483724

So relieved. The face of the spindle where the backing plate contacts needs to be lightly trued. It is slightly mushroomed.

My Fairmount wrench is now a 1 3/8" opening to 1 7/16". I'll have to buy a new 1 5/16" to replace it. Lol.

I ended up pinching a 4x6 under one of the jaws stuck out about half way. Then I put a prybar into the pulley and used the gear reduction to finally break it loose.