- Joined

- Apr 23, 2018

- Messages

- 6,537

You must've gone south to where it never snows. They have Summer teeth from meth and sunshine. Summer there, summer not.I visited a certain state recently, Counting TEETH there was quite easy!

You must've gone south to where it never snows. They have Summer teeth from meth and sunshine. Summer there, summer not.I visited a certain state recently, Counting TEETH there was quite easy!

More likely, the gear selector rail is off by one gear. Perhaps, a P.O. did some work on the gear box and reassembled it incorrectly.

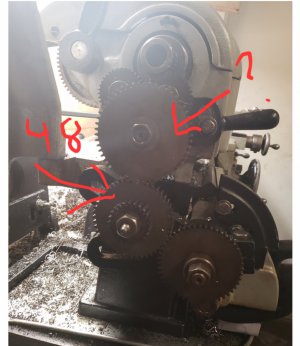

I did count teeth. On the stud gear at least. 48.Time to start counting teeth. Harbor Freight has a tool for that!

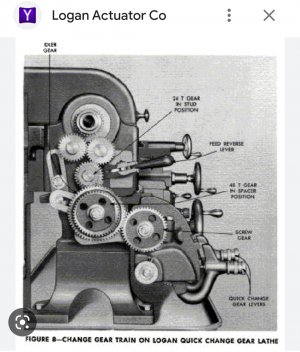

Right, it looked like the manual picture before I swapped to the 48t stud gear.I just found this picture...

The placement of the gears on your lathe don't seem to match what is in the picture...

You may want to check and make sure all of the gears are installed in their correct locations...

Here is a picture of my Logan before it was disassembled...

View attachment 446462

I'm missing one of the reversing gears in the picture...

The 36t gear is mounted on the stud and the 72t gear is 'in storage' on the sector. In your picture, it appears that you have a larger (maybe 54t) gear on the stud with your 48t gear on the sector. I don't know if that would make a difference, as it seems the overall gear ratio would remain the same.

Just a suggestion.

-Bear

Mystery solved! I am an idiot!I've done my best to count the teeth on the gears in your picture... the one on the stud looks to be a 54t? The 48t is in the position of the idler gear...

View attachment 446463

I think they should be swapped...

Am I correct about this? I'm not trying to be argumentative... just trying to clarify...

If you do determine that you need a different gear or gears, let me know... I may have what you need... assuming that your gears are a 16DP...

-Bear