- Joined

- Dec 11, 2014

- Messages

- 891

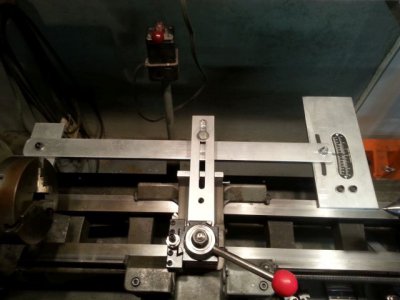

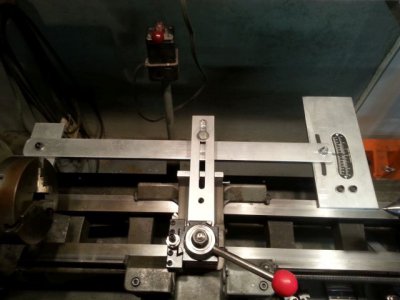

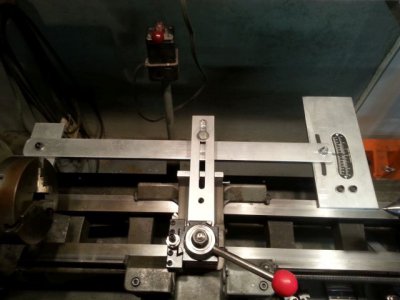

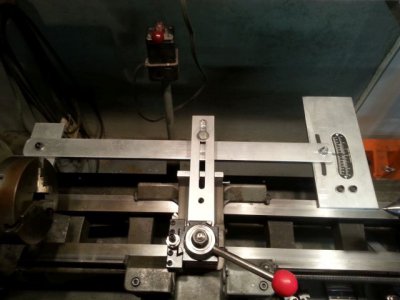

First I made a Taper attachment for my Craftsman Commercial 12 x 36.

Next is my ER40 Collet Chuck I am in the process of finishing. Just waiting on the Nut to be delivered so I can finish the Metric threading.

The next is a new holder for my QCTP able to hold 5/8" bits.

I also made a new boring and threading bar holder for a 1/2" threading bar I purchased.

That's it so far.

I'll be making some more holders as I get tired of changing out tool bits all of the time.

Need to make some kind of holder to hold all of them also.

If anyone has one or plans for building one, I would appreciate seeing them.

Next is my ER40 Collet Chuck I am in the process of finishing. Just waiting on the Nut to be delivered so I can finish the Metric threading.

The next is a new holder for my QCTP able to hold 5/8" bits.

I also made a new boring and threading bar holder for a 1/2" threading bar I purchased.

That's it so far.

I'll be making some more holders as I get tired of changing out tool bits all of the time.

Need to make some kind of holder to hold all of them also.

If anyone has one or plans for building one, I would appreciate seeing them.