In the process of setting up my new PM-940V. It is the basic model with hardened ways but no PDF. Eventually will do a CNC conversion with the ArizonaVideo99 kit with HD Z axis ballscrews. In the meantime, I will use the mill manually so am installing the TouchDRO system. I have the same DRO on my LMS Hi Torque 7500 lathe, and it was a simple setup.

Claugh42 did a great set of videos doing the scale install on a PM-940M. I am taking a slightly different approach, mainly in that I will 3d print all my parts.

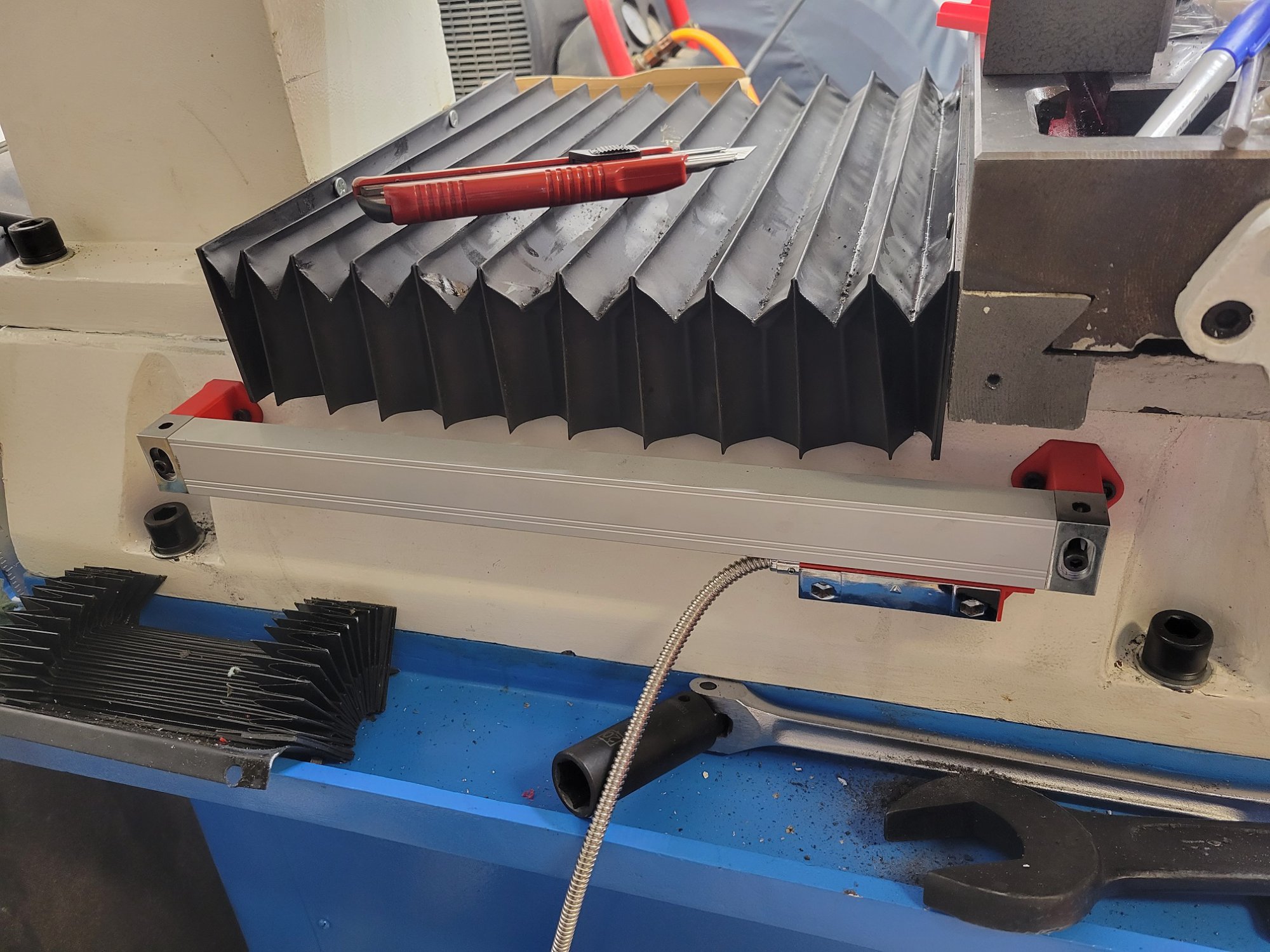

Here is the first step on the Y-Axis. Probably should have ordered a longer scale for this axis. it has 12" of travel, but because of the mounting bolts on the base I have to work around those cutouts. The left hand red bracket needed to be shimmed out 1.5mm to get tracking within a couple thou down the length of the scale. I printed a simple shim cap to sit under the scale. The table is in the most forward position in this photo. Next step is the plate to bolt onto the end of the carriage to mount to the sensor. There is about a 5mm offset between the plane of the carriage and the sensor, so that offset will be built into the plate. The parts are made out of red PLA for testing. Once the dimensions are dialed in the final parts will probably use CF PETG, just because the parts look nice.

Claugh42 did a great set of videos doing the scale install on a PM-940M. I am taking a slightly different approach, mainly in that I will 3d print all my parts.

Here is the first step on the Y-Axis. Probably should have ordered a longer scale for this axis. it has 12" of travel, but because of the mounting bolts on the base I have to work around those cutouts. The left hand red bracket needed to be shimmed out 1.5mm to get tracking within a couple thou down the length of the scale. I printed a simple shim cap to sit under the scale. The table is in the most forward position in this photo. Next step is the plate to bolt onto the end of the carriage to mount to the sensor. There is about a 5mm offset between the plane of the carriage and the sensor, so that offset will be built into the plate. The parts are made out of red PLA for testing. Once the dimensions are dialed in the final parts will probably use CF PETG, just because the parts look nice.