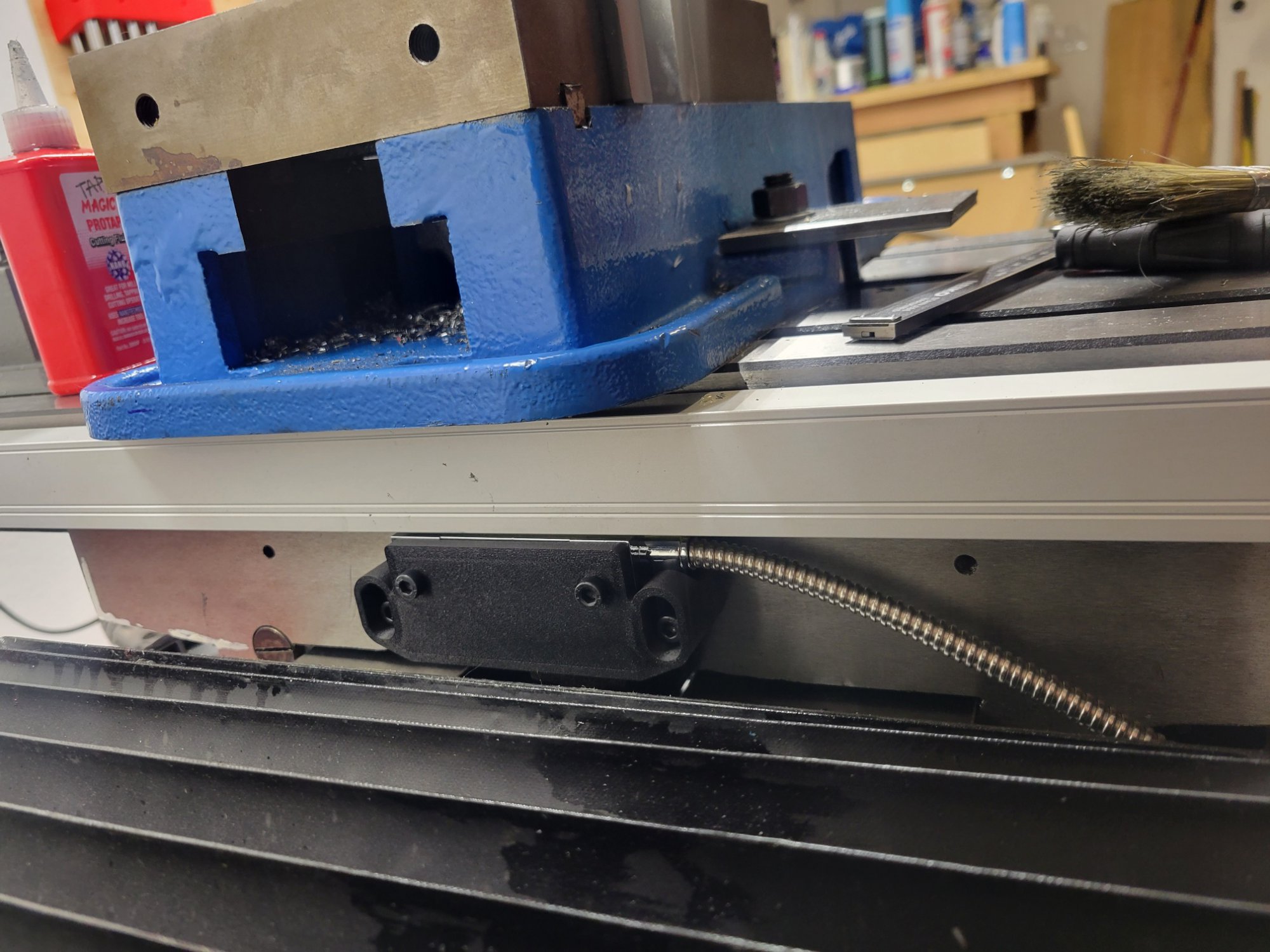

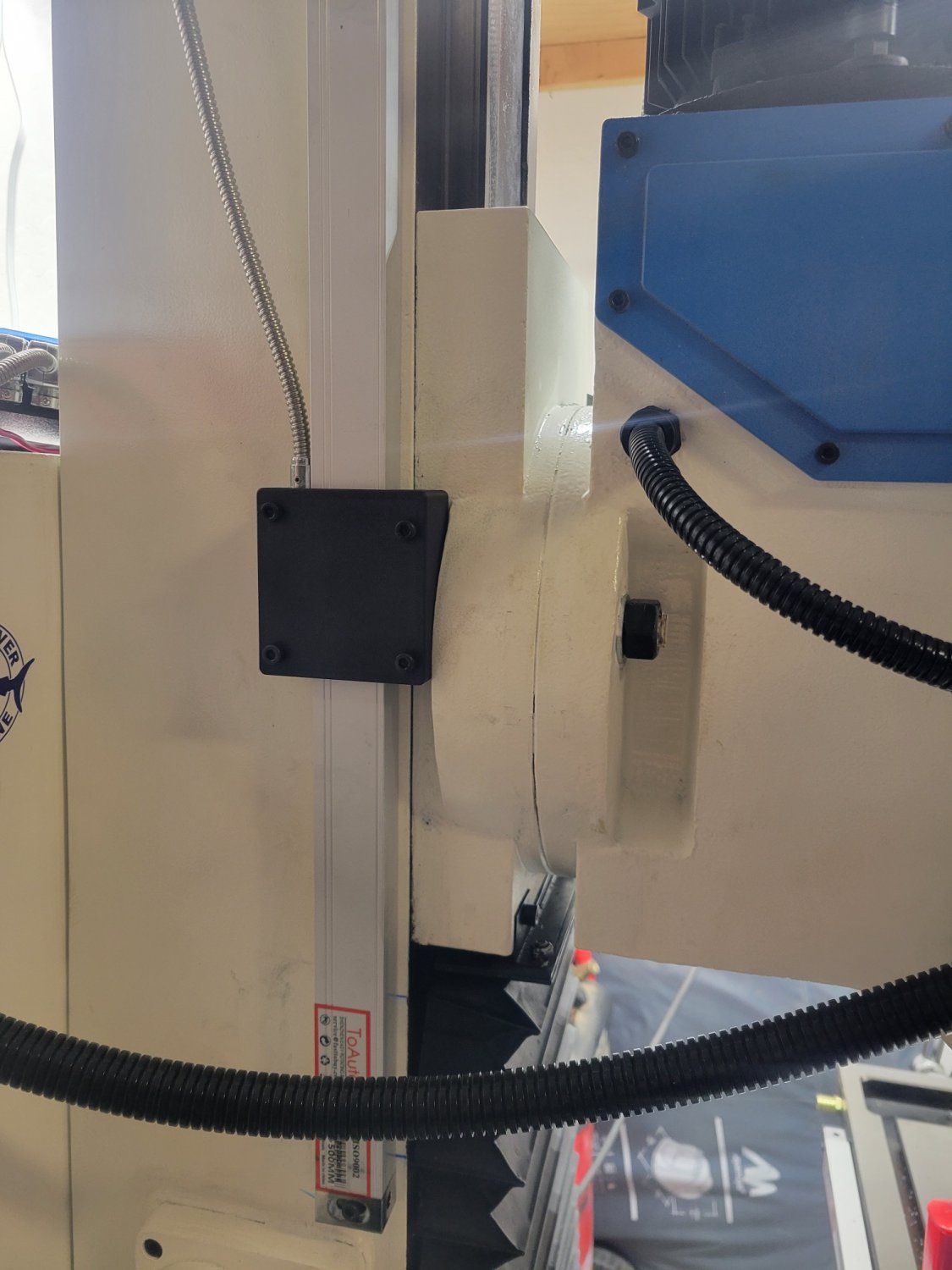

The scales are installed and calibrated. Here is the X axis Sensor mount. I added 2mm shims under the end of the scale to leave a gap between the table. Will mount the aluminum chip guard and slip the edge into the gap. I am also printing a spacer block 30mm thick to mount on each side of the sensor. The accordian will then screw into that block.

Last detail is to clean up the cable runs and mount the TouchDRO case on the cabinet somewhere. I also ordered a 5v DIN rail power supply to mount inside the electronics cabinet. Then will add a thru panel dual USB port to provide power for the Tablet and TouchDRO box.

The tablet is mounted and sitting very securely. 3d printed brackets and 3m mounting tape. Found some 8mm leadscrew and cut it down for the post.

Last detail is to clean up the cable runs and mount the TouchDRO case on the cabinet somewhere. I also ordered a 5v DIN rail power supply to mount inside the electronics cabinet. Then will add a thru panel dual USB port to provide power for the Tablet and TouchDRO box.

The tablet is mounted and sitting very securely. 3d printed brackets and 3m mounting tape. Found some 8mm leadscrew and cut it down for the post.