I purchased a used Vevor MX-8 x 14 lathe for converting to cnc. I do not believe it has too many hours on it as only one tool was used. The previous owner tired of the low power and spindle stopping when it had too much load, purchased a larger machine. It came with extra belts and quick-change tool post with 5 holders.

Currently, the lathe sits disassembled and very plain on the workbench. Just the bed, headstock and spindle remain.

What I know needs done:

Replace spindle bearings in headstock. The spindle is so stiff it will almost sit solid with a bolt in the chuck and a 12" Crescent wrench positioned horizontally on bolt.

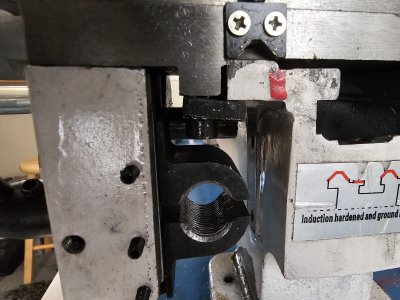

Shim saddle for proper clearance and operation. There are no shims between the saddle and saddle retainer on the underside of the ways resulting in a poor fit and clearance under the ways.

The saddle lead screw has very close fit and operates very well.

The cross slide lead screw is very loose and needs to be replaced.

The compound is fine and holds the quick-change tool holder

Make a motor mount for the new DC motor

Preliminary Plans: (in order...omitting small steps and likely to change)

Remove spindle bearings

Degreasing and paint

Check spindle for trueness and fit to chuck.

Install spindle bearings and spindle

Make motor mount, add motor and pulleys

Add encoder plate to spindle and mount encoder to head stock

Add ball screw, mounts and nut to saddle z travel

Make mount for z travel stepper, mount motor, add pulleys and install belt

Add ball screw, mounts and nut to cross slide x travel

Make mount for x travel stepper, mount motor, add pulleys and install belt

Install limit switches

Install controller, drivers and wiring

Install lubrication sump and pump

Addition of bed bellows to catch waste and protect ways from damage

Components I currently have:

2.0hp treadmill motor with over-temp switch and controller from treadmill

Mach USB controller card

2 23HS22-2804S-PG47 stepper with 47:1 planetary gearbox. I plan to use without the gearbox as I have plans for them. This leaves 2.8A 1.25Nm(177.01oz.in) steppers

2 TB6600 4A 9-42V Stepper Drivers (ordered)

1 24V 480W power supply (ordered)

1 Omron E6B2-CWZ6C Rotary Encoder (Incremental) 5-24V 1024P/R

4 mini lever limit switches

Components to order:

Taper roller bearings

Motor timing pulley

Spindle timing pulley for encoder

Encoder timing pulley

Ball screw for saddle travel

Ball screw for cross slide travel

Questions:

What spindle RPMs? A 2.0HP, 3,500 RPM motor with 1:3 timing pulleys should be strong enough to turn the spindle up to 10,500 RPM for cuts and still be able to turn slow enough for good threading?

I have the original spindle timing pulley and need to order the proper motor pulley and need to know if I need to fit the motor timing pulley to the motor or the flywheel. So, I need to know if I should keep the flywheel or remove the flywheel and make/find a fan to cool the motor. Any suggestions?

I also wonder if I should tilt the lathe forward by 45 degrees by making a solid concrete base to mount the lathe to for a more vibration free operation? Would the 45 degree tilt really help with waste removal and lubricant collection?

I plan to use Mach3 for now, only because I am familiar with Windows a little more than Linux, but would like to transition to LinuxCNC later when I make a 5-axis mini mill to pair with the lathe.

Currently, the lathe sits disassembled and very plain on the workbench. Just the bed, headstock and spindle remain.

What I know needs done:

Replace spindle bearings in headstock. The spindle is so stiff it will almost sit solid with a bolt in the chuck and a 12" Crescent wrench positioned horizontally on bolt.

Shim saddle for proper clearance and operation. There are no shims between the saddle and saddle retainer on the underside of the ways resulting in a poor fit and clearance under the ways.

The saddle lead screw has very close fit and operates very well.

The cross slide lead screw is very loose and needs to be replaced.

The compound is fine and holds the quick-change tool holder

Make a motor mount for the new DC motor

Preliminary Plans: (in order...omitting small steps and likely to change)

Remove spindle bearings

Degreasing and paint

Check spindle for trueness and fit to chuck.

Install spindle bearings and spindle

Make motor mount, add motor and pulleys

Add encoder plate to spindle and mount encoder to head stock

Add ball screw, mounts and nut to saddle z travel

Make mount for z travel stepper, mount motor, add pulleys and install belt

Add ball screw, mounts and nut to cross slide x travel

Make mount for x travel stepper, mount motor, add pulleys and install belt

Install limit switches

Install controller, drivers and wiring

Install lubrication sump and pump

Addition of bed bellows to catch waste and protect ways from damage

Components I currently have:

2.0hp treadmill motor with over-temp switch and controller from treadmill

Mach USB controller card

2 23HS22-2804S-PG47 stepper with 47:1 planetary gearbox. I plan to use without the gearbox as I have plans for them. This leaves 2.8A 1.25Nm(177.01oz.in) steppers

2 TB6600 4A 9-42V Stepper Drivers (ordered)

1 24V 480W power supply (ordered)

1 Omron E6B2-CWZ6C Rotary Encoder (Incremental) 5-24V 1024P/R

4 mini lever limit switches

Components to order:

Taper roller bearings

Motor timing pulley

Spindle timing pulley for encoder

Encoder timing pulley

Ball screw for saddle travel

Ball screw for cross slide travel

Questions:

What spindle RPMs? A 2.0HP, 3,500 RPM motor with 1:3 timing pulleys should be strong enough to turn the spindle up to 10,500 RPM for cuts and still be able to turn slow enough for good threading?

I have the original spindle timing pulley and need to order the proper motor pulley and need to know if I need to fit the motor timing pulley to the motor or the flywheel. So, I need to know if I should keep the flywheel or remove the flywheel and make/find a fan to cool the motor. Any suggestions?

I also wonder if I should tilt the lathe forward by 45 degrees by making a solid concrete base to mount the lathe to for a more vibration free operation? Would the 45 degree tilt really help with waste removal and lubricant collection?

I plan to use Mach3 for now, only because I am familiar with Windows a little more than Linux, but would like to transition to LinuxCNC later when I make a 5-axis mini mill to pair with the lathe.