- Joined

- Nov 17, 2019

- Messages

- 22

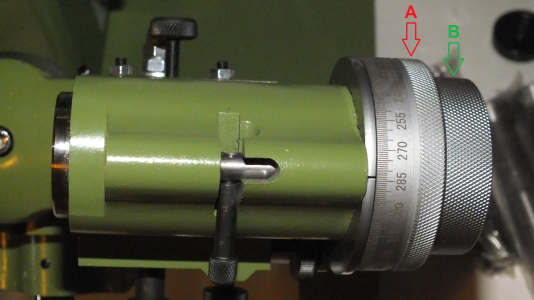

I recently purchased a Suying U3 Universal Cutter Grinder and the user manual is next to useless. I think it is a Deckel clone. I have watched a number of YouTube videos and have come to the conclusion that my unit has some defects/deficiencies. It came with three or four attachments and the main one is for sharpening end mill bits. The tube that accepts collets turns a full 360° (see photo). There is a 3-position lever (middle of photo 1) that is supposed to ① allow free rotation ② limit rotation to 180° ③ lock to current position. The lever on my unit, when in ③ has the same behavior as position ②. The end of the tube (photo 2) where the draw wheel attaches to the collet has a nut on the end where you can, apparently, remove the knurled dials with the angle guage and take the thing appart. It would require a special kind of spanner wrench with four points of attachment. What are these called and where could I get an inexpensive one? The four slots for accommodating the jaws are 32mm apart. If I can't fix the lever's operation, I may be able to drill a hole in the cylinder and use one of those adjustable handle locks that are used elsewhere on the machine for locking various things in place.

Attachments

Last edited: