- Joined

- Jul 20, 2014

- Messages

- 182

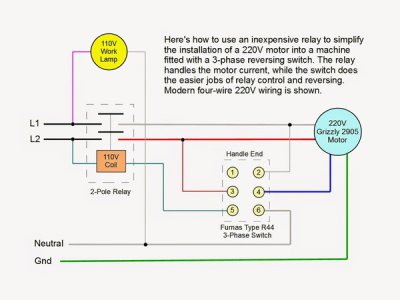

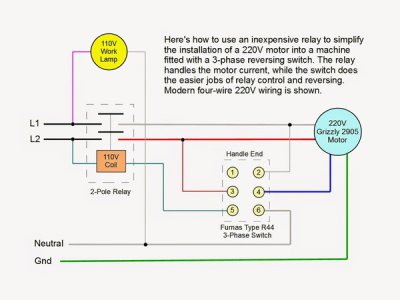

I recently bought a Grizzly G2905 1-hp motor to go in my lathe. (BTW... These are on sale right now for $115.) Anyway I felt uncomfortable with the wiring solutions presented because Grizzly re-connects a single wire to get the motor to reverse direction.

My lathe has the Furnas R-44 type switch designed for use with 3-phase, and it looked like the purchase of a $50 R-1 switch might be required. Then a much simpler, safer, and far less expensive solution dawned on me. By inserting a 2-pole air conditioner relay into the circuit to control the motor current, the "motor reversing switch" is left only to swap the capacitor connection and control the coil in the relay. Best of all, two-pole, 15-20A relays of this type are available on Ebay in the $8 range.

The relay I purchased has a 110VAC coil and the contacts are rated for 3x the motor current, since I imagine that the "starting" load can be quite a bit higher than the listed "running" current.

Maybe this will help someone.

My lathe has the Furnas R-44 type switch designed for use with 3-phase, and it looked like the purchase of a $50 R-1 switch might be required. Then a much simpler, safer, and far less expensive solution dawned on me. By inserting a 2-pole air conditioner relay into the circuit to control the motor current, the "motor reversing switch" is left only to swap the capacitor connection and control the coil in the relay. Best of all, two-pole, 15-20A relays of this type are available on Ebay in the $8 range.

The relay I purchased has a 110VAC coil and the contacts are rated for 3x the motor current, since I imagine that the "starting" load can be quite a bit higher than the listed "running" current.

Maybe this will help someone.