- Joined

- Feb 17, 2013

- Messages

- 336

I picked up one of these in need of some love and I'm wondering if any one knows where I can get a manual and parts list for it.

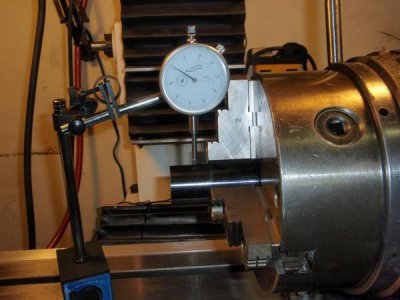

http://www.vertex-tw.com.tw/products/products_list.php?cid=15

http://www.vertex-tw.com.tw/products/products_list.php?cid=15