I keep coming across projects that need a small amount of milling. I have read a lot of peoples comments on how they are junk. For someone without a drill press or any other means of milling I am starting to consider adding a 4"x5" vertical mill table to my lathe.

https://www.ebay.com/itm/LATHE-VERT...893189&hash=item4b475b555c:g:9QoAAOSwxBtbbSAa

It looks like I would also need some sort of clamping set up to hold my work.....

https://www.harborfreight.com/42-piece-machinist-clamping-kit-90752.html

I know you all have way more in sight on this than I do having never used a mill.

https://www.ebay.com/itm/Combo-of-R...922244?hash=item4b4b014784:g:6REAAOSwstJZOrR3

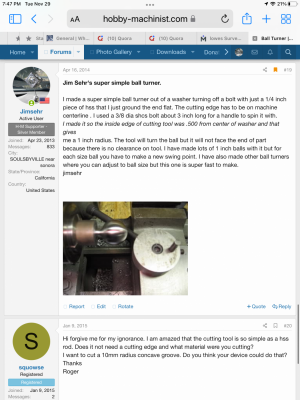

I was wanting to make a ball turning tool for my lathe and see that it requires a slot milled out.

Let me know your thoughts on this.

https://www.ebay.com/itm/LATHE-VERT...893189&hash=item4b475b555c:g:9QoAAOSwxBtbbSAa

It looks like I would also need some sort of clamping set up to hold my work.....

https://www.harborfreight.com/42-piece-machinist-clamping-kit-90752.html

I know you all have way more in sight on this than I do having never used a mill.

https://www.ebay.com/itm/Combo-of-R...922244?hash=item4b4b014784:g:6REAAOSwstJZOrR3

I was wanting to make a ball turning tool for my lathe and see that it requires a slot milled out.

Let me know your thoughts on this.