-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vevor 250 x 750 Lathe Upgrades

- Thread starter lesrhorer

- Start date

Phase II: Motor

They were supposed to ship me a lathe with an 1100 Watt motor, but they sent one with a 750 Watt motor by mistake. Rather than ship the entire system back, they refunded me the cost of a 1200 Watt motor. The original was a higher speed brushed DC motor, but the new one is a 3000RPM brushless motor.

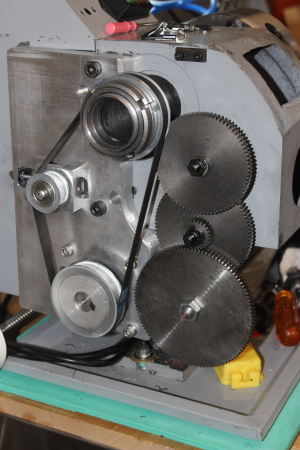

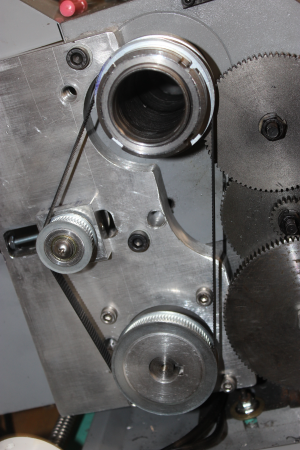

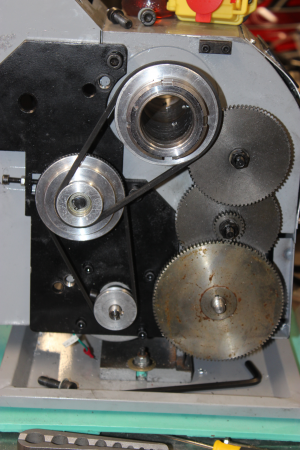

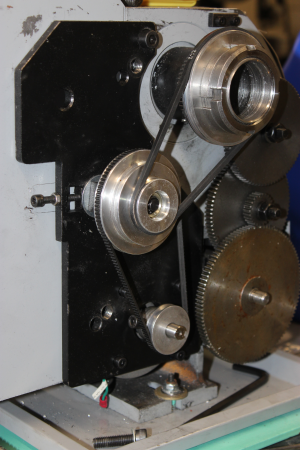

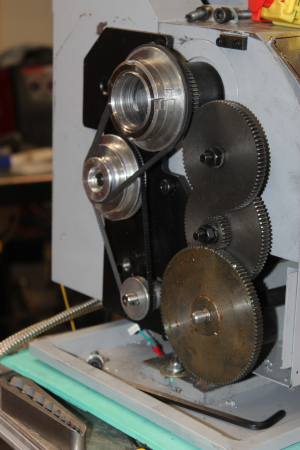

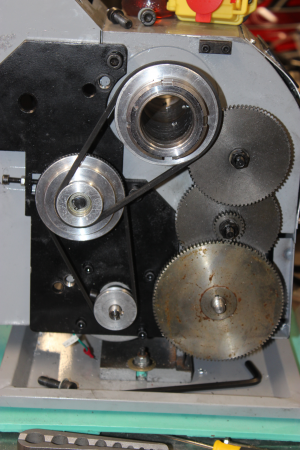

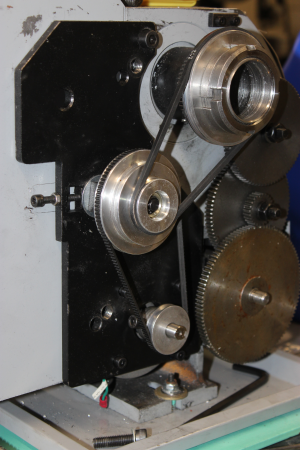

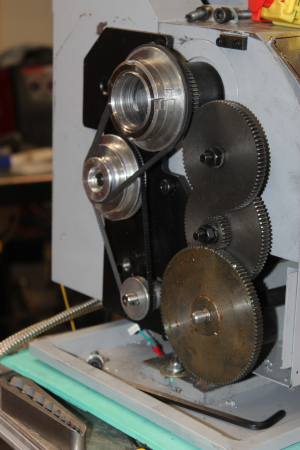

The original design employed a 3 position idler cone pulley and a 2 position cone pulley on the spindle, using tiny V-belts to allow for two spindle speed ranges. V-belts (especially ones this tiny) can tend to slip and one of them shredded itself within a few hours of operation. The new motor should allow the lathe to operate across a wider speed rage (3000RPM vs. 1250 / 2500 RPM) with higher torque, without the need for belt changes. The original idler bracket was poorly made, with a very sloppy fit and poor registration.

In addition, I changed the V-belt pulleys out for timing belt pulleys, which should prevent slipping. If the torque turns out to be too low at the low and high ranges, I will change out the motor pulley to one with fewer teeth.

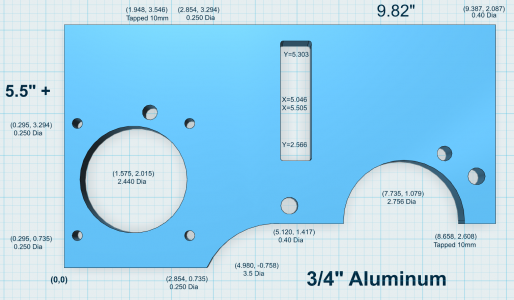

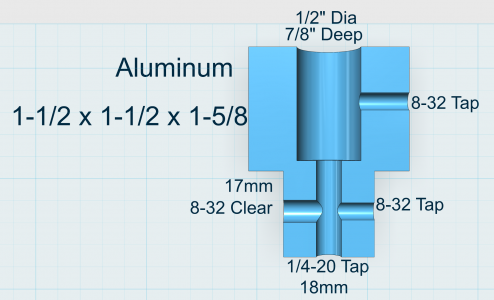

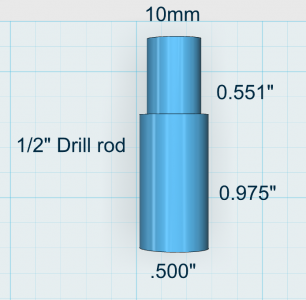

In order to maintain tension on the belt, I designed an idler pulley with a threaded rod adjustment. This is an idler only, not a transmission gear.

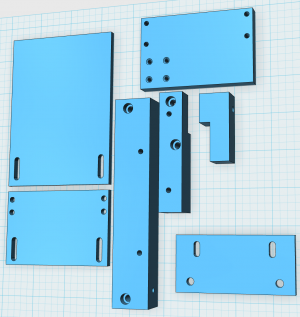

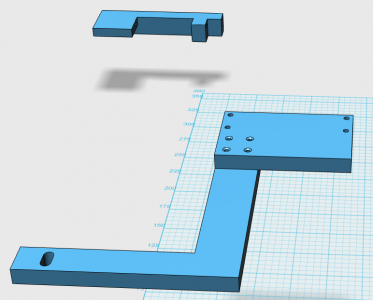

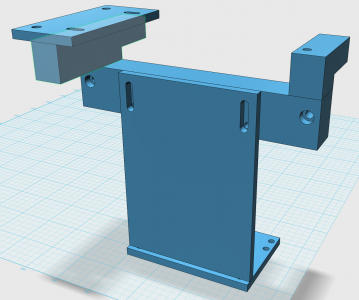

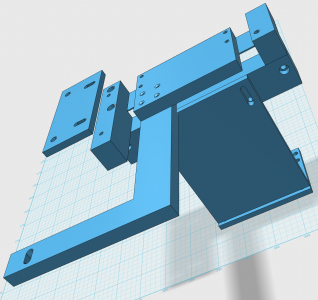

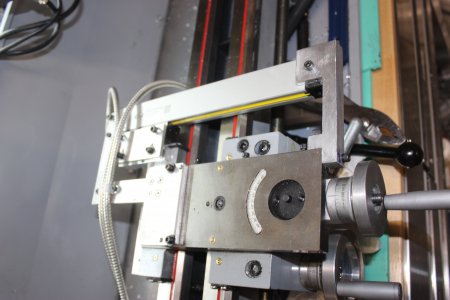

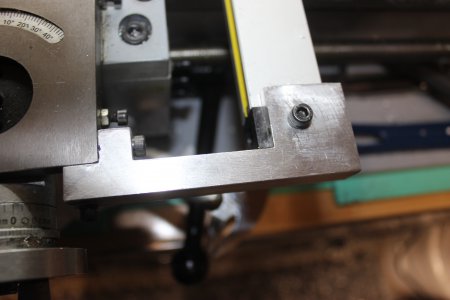

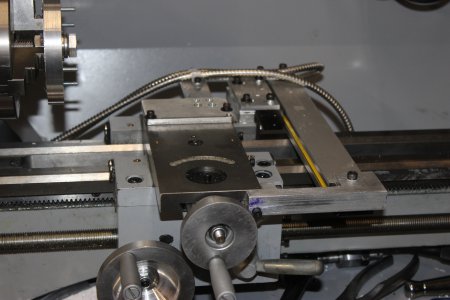

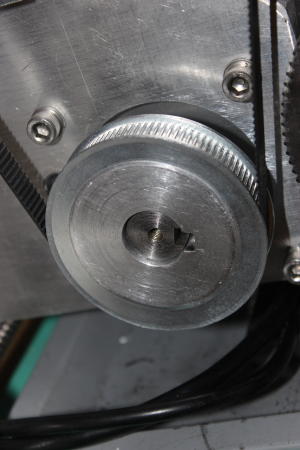

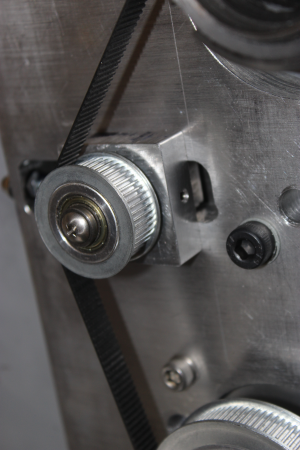

Here are photos of the original design, which employed a 4mm steel motor mount:

They were supposed to ship me a lathe with an 1100 Watt motor, but they sent one with a 750 Watt motor by mistake. Rather than ship the entire system back, they refunded me the cost of a 1200 Watt motor. The original was a higher speed brushed DC motor, but the new one is a 3000RPM brushless motor.

The original design employed a 3 position idler cone pulley and a 2 position cone pulley on the spindle, using tiny V-belts to allow for two spindle speed ranges. V-belts (especially ones this tiny) can tend to slip and one of them shredded itself within a few hours of operation. The new motor should allow the lathe to operate across a wider speed rage (3000RPM vs. 1250 / 2500 RPM) with higher torque, without the need for belt changes. The original idler bracket was poorly made, with a very sloppy fit and poor registration.

In addition, I changed the V-belt pulleys out for timing belt pulleys, which should prevent slipping. If the torque turns out to be too low at the low and high ranges, I will change out the motor pulley to one with fewer teeth.

In order to maintain tension on the belt, I designed an idler pulley with a threaded rod adjustment. This is an idler only, not a transmission gear.

Here are photos of the original design, which employed a 4mm steel motor mount:

Last edited: