A

Andre

Forum Guest

Register Today

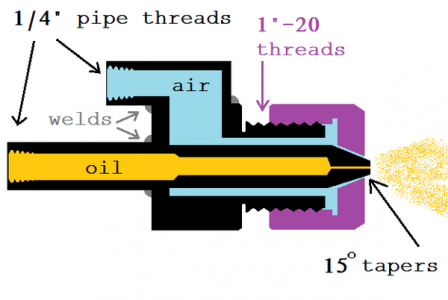

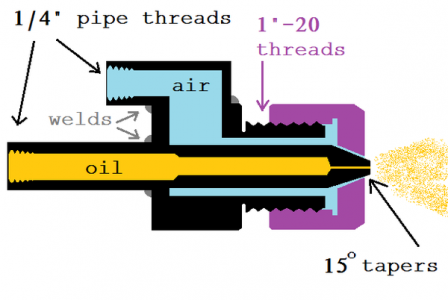

I'd like to try making a waste oil foundry, and will start on a atomizer nozzle today. If it fails, I'm in need of a backup plan. Does anybody have plans for a atomizer nozzle?

This is the one I'm trying today: http://home.cogeco.ca/~woproject/images/Nozzle.jpg

Thanks!

This is the one I'm trying today: http://home.cogeco.ca/~woproject/images/Nozzle.jpg

Thanks!