Hi All,

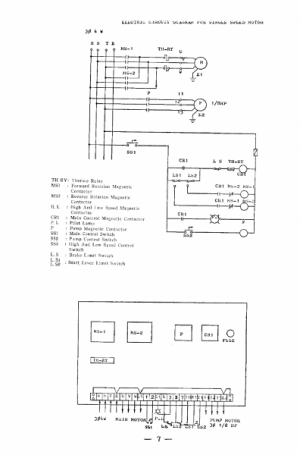

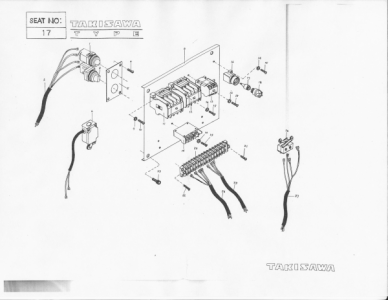

Does anyone have some good pictures of the wiring of this beast - prefer the single speed. The PO made a real mess of things, and I need to rewire to get it to run - It was running in their shop... Lots of 'fixes', that need to now be fixed... my email rbahr the number 1900, followed by yahoo.com

I do realize that one O them nice VFDs would clear up a lot of problems, but I have a nice RPC, and $500 is just not currently in the budget...

Has anyone reached Green Bay Manu.?

Thanks in advance...

Ray

Does anyone have some good pictures of the wiring of this beast - prefer the single speed. The PO made a real mess of things, and I need to rewire to get it to run - It was running in their shop... Lots of 'fixes', that need to now be fixed... my email rbahr the number 1900, followed by yahoo.com

I do realize that one O them nice VFDs would clear up a lot of problems, but I have a nice RPC, and $500 is just not currently in the budget...

Has anyone reached Green Bay Manu.?

Thanks in advance...

Ray