-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Westinghouse electric motor

- Thread starter Lapowers

- Start date

This probably not much help, but are there five wires sticking out or are there five terminals? If you have five terminals, get a flashlight and look closely at the base. They may have a letter or number mark . If you see L1 and L2, then these are probably the hot and neutral terminals you connect to. The other terminals are most likely for wiring for 220 or reversing the rotation.I bought a south bend lathe with a westinghouse 1/2 hp motor 115 volt style801038 series Ed there is no wiring diagram and I'm not sure how to wire it there are 5 wires was wondering if anyone had any insight

If you just have five loose wires, its going to be harder to figure out.

Good luck

Look at this thread, it has some pictures showing typical details.This probably not much help, but are there five wires sticking out or are there five terminals? If you have five terminals, get a flashlight and look closely at the base. They may have a letter or number mark . If you see L1 and L2, then these are probably the hot and neutral terminals you connect to. The other terminals are most likely for wiring for 220 or reversing the rotation.

If you just have five loose wires, its going to be harder to figure out.

Good luck

http://www.hobby-machinist.com/showthread.php?t=16527

I don't recognize any of the wire labels you found, but I'm not a motorman

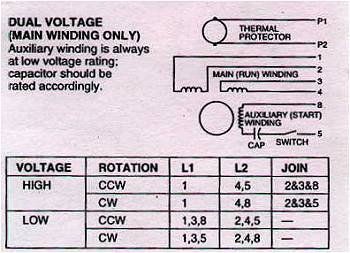

I would suspect the above diagram is what your motor should be. In other words 110/220, reversible.Ignore the P1 and P2 ,your motor may not have a thermal protector. I would first identify the Aux or start winding. The motor should have a centrifugal start switch and its leads will go to the start wind or starting Capacitor. It also may not have a Capacitor . If you don't see one on the motor, it doesn't.

You will need an ohmmeter to identify the Run windings. If you can identify the four wires that go to the two run windings, for 110 volt use they will be connected in parallel as shown in the table above. You are probably going to have to make some guesses and plug it in and see what happens. With a little luck and if you plug and unplug real quick you won't hurt it.

Hope this helps.

- Joined

- Feb 2, 2013

- Messages

- 3,627

does the motor have a capacitor(s)?

- Joined

- Dec 8, 2013

- Messages

- 2,651

No capacitor unless its inside the motor also I just noticed its a dc motor 115 volts 4.7 amps

How did you conclude that?