-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What Rong Fu mill is this?

- Thread starter ridgeway

- Start date

- Joined

- Nov 26, 2011

- Messages

- 10

Ridgeway, I just picked up a mill from the local scrap yard that is just like yours. No makings of any kind as to who built it. It has the power feed and I think I have figured out how all the speeds work. I would like to find out how to drain and change the oil in the feed gearboxes and also what oil to use. I have searched the internet, posted pictures on several forums, and even emailed Rong Fu but so far had no luck. Let me know if you find out anything please.

- Joined

- Nov 10, 2013

- Messages

- 837

Last edited:

while we are it can anyone identify this?

This was a crags list mill. I believe it to be an old Rong fu. What I can't figure out are the speeds and speed changes. There are 4 separate pulleys. Do I need to use 3 belts for it? Or have a bunch in different sizes depending on which pulley?

Thanks, new to the group.

Al

This was a crags list mill. I believe it to be an old Rong fu. What I can't figure out are the speeds and speed changes. There are 4 separate pulleys. Do I need to use 3 belts for it? Or have a bunch in different sizes depending on which pulley?

Thanks, new to the group.

Al

- Joined

- Jan 23, 2012

- Messages

- 1,216

whats that pulley shown behind the column in the top picture ? another machine ?

as far as belts for the rong fu, only two are required, the center jack shaft that rotates around the column changes its location depending on which combo of pulleys you choose. its kind of a pain in the butt changing speeds but. . . . . .

this is when I should install the 3 phase motor and phase controller. .

as far as belts for the rong fu, only two are required, the center jack shaft that rotates around the column changes its location depending on which combo of pulleys you choose. its kind of a pain in the butt changing speeds but. . . . . .

this is when I should install the 3 phase motor and phase controller. .

- Joined

- Nov 26, 2011

- Messages

- 10

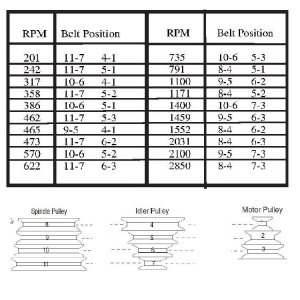

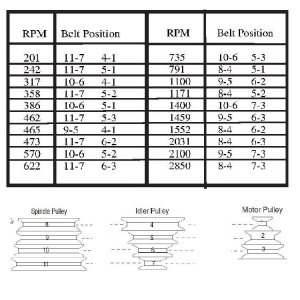

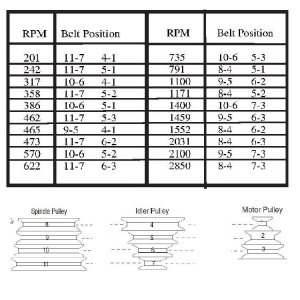

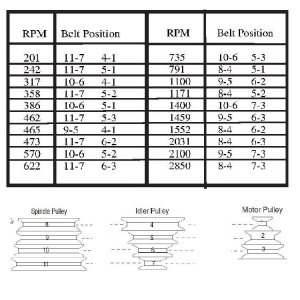

babar, Looks like you have a different Rong Fu than the rest of us have. With the four pulleys , yes you will need three belts. Appears the motor pulley is just two steps. The usual three four step pulley setup gives 12 speeds. With that extra pulley you should have more but I would have to draw it out and do some figuring to see how many. When I got my mill it didn't have a motor so no motor pulley. I happened to have a 3 step pulley that would fit the new motor shaft so used it. I also happened to have a hand held digital tach. It has a little cone on the end of the shaft and I put a 3/8" collet in spindle and could hold the tach to that and get a reading. I moved the belts around and recorded the speeds. With the three step pulley I can loosen the

set screws and slide it up or down to give a couple more speeds. If I wanted to keep a shorter belt handy, I could get another two or three speeds but don't see the use of it. I then made up this chart, sealed it in plastic, and taped it to side of mill. Hope this helps.

If I wanted to keep a shorter belt handy, I could get another two or three speeds but don't see the use of it. I then made up this chart, sealed it in plastic, and taped it to side of mill. Hope this helps.

set screws and slide it up or down to give a couple more speeds.

If I wanted to keep a shorter belt handy, I could get another two or three speeds but don't see the use of it. I then made up this chart, sealed it in plastic, and taped it to side of mill. Hope this helps.

If I wanted to keep a shorter belt handy, I could get another two or three speeds but don't see the use of it. I then made up this chart, sealed it in plastic, and taped it to side of mill. Hope this helps.

whats that pulley shown behind the column in the top picture ? another machine ?

as far as belts for the rong fu, only two are required, the center jack shaft that rotates around the column changes its location depending on which combo of pulleys you choose. its kind of a pain in the butt changing speeds but. . . . . .

this is when I should install the 3 phase motor and phase controller. .

yup. That is kind of what I was thinking.

- - - Updated - - -

That is pretty helpful. I was thinking that for a high speed, I could run a long belt directly from the motor to the spindle, and then add belt as needed, to cut the speeds down. Its weird also, because the pulleys are not fixed, and move around the center column.

babar, Looks like you have a different Rong Fu than the rest of us have. With the four pulleys , yes you will need three belts. Appears the motor pulley is just two steps. The usual three four step pulley setup gives 12 speeds. With that extra pulley you should have more but I would have to draw it out and do some figuring to see how many. When I got my mill it didn't have a motor so no motor pulley. I happened to have a 3 step pulley that would fit the new motor shaft so used it. I also happened to have a hand held digital tach. It has a little cone on the end of the shaft and I put a 3/8" collet in spindle and could hold the tach to that and get a reading. I moved the belts around and recorded the speeds. With the three step pulley I can loosen the

set screws and slide it up or down to give a couple more speeds. View attachment 70008If I wanted to keep a shorter belt handy, I could get another two or three speeds but don't see the use of it. I then made up this chart, sealed it in plastic, and taped it to side of mill. Hope this helps.

- Joined

- Nov 26, 2011

- Messages

- 10

babar, the pulleys have to swing around the column to allow you to swap belts on the pulleys. There should be a spring loaded plunger behind the unhinged side of the motor mount. It should have a locking screw to lock the plunger in place. What you do to change speeds is loosen the locking screw, push the motor back toward the mill head and lock the screw to hold the plunger back. That should loosen the first belt. Then you loosen the two screws that hold the idler pulley bracket and that should let you swing the pulleys to loosen the other belts. Rearrange the belts to the speed you want. Then loosen the plunger lock screw and the plunger will push the motor mount out tightening all the belts. If you want you can pull out on motor mount to put a little extra tension on the belt and then tighten the locking screw to hold the tension. Then snug the bolts that lock the idler pulley bracket and you are good to go. Hope I explained it good enough. If not I can take some pictures. Changing speeds is not that big a deal and once you have done it a few times it is pretty fast. One belt from the small pulley on motor to any of the pulleys on the spindle will NOT give you the highest speed. To get the highest speed some of the belts will go from a big pulley to a small pulley.