Acetone usually ruins most build plates unless they're just a glass surface. Even my carbon coated build plate will eventually be ruined by acetone....acetone??

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why is there an outline around the part printed?

- Thread starter WobblyHand

- Start date

send me your .stl and I'll try printing it vertical and see what I get.I don't know why either. I basically did what you wrote, and the results were not as expected.

There's a couple of mitigating factors, I was printing thin walls vertically because my bigger piece had vertical thin walls, and maybe the filament was damp. The PETG has been in a tight bag with silica gel for a while now. I'll try again in a bit.

Unfortunately when I printed a thin structure test cube in vase mode, the 40 x 40mm base sort of fused to the sheet. Can't get rid of all of it. Most of it is gone, but it's maybe 0.25mm higher in the dead middle of the satin sheet. Can I use a metal scraper to get it off? Tried a pla scraper but it didn't take off much.

Or; upload it to thingiverse and post a link to it.

I use the latest version of cura and a modified version of Marlin, and my hardware is reality cr10 V3 with an e3d vicano hot end and titan direct extruder.

So not sure if my settings would be transferable to your hardware/software. Might give you a starting point though…

Last edited:

Can I use a metal scraper to get it off?

I use a metal putty knife that I’ve sharpened. You need to peel the PETG off the surface, so getting under the edge is key. Round the scraper’s corners before sharpening the edge, to minimize damage from the corners digging in.

To get the material off your satin sheet try putting it on the printer and heat the bed to 85C or so. Then take it off (use gloves) and bend it slightly while carefully scraping the residue off with a new razor blade held at a very low angle. Reheat if necessary. You’ll be able to get most of it off or at least to the point that it’s usable again.

The best surface I have found for printing PETG on is blue painters tape over the entire build surface. I also insert a few custom lines of G-code that first brings the bed up to temp, and then waits for 2 minutes to allow the temperature to equalize across the bed surface. The bed does not heat up super evenly, if you watch it with an FLIR camera you can see the shape of the heating elements. After the 2 minutes the temp has spread out to fairly even.

I always use a 8mm brim on my prints, It helps a lot to keep the corners down on both PETG and PLA.

M117 Stabilizing Temps. ;Indicate stabilizing temps.

G4 S120 ;pause 120 seconds to allow bed to stabilize temps

I always use a 8mm brim on my prints, It helps a lot to keep the corners down on both PETG and PLA.

M117 Stabilizing Temps. ;Indicate stabilizing temps.

G4 S120 ;pause 120 seconds to allow bed to stabilize temps

Got to get back to this. Took a little break. Need to clean / scrape / razor off the satin plate tomorrow. Once it is cleaned up, I can give it another try.

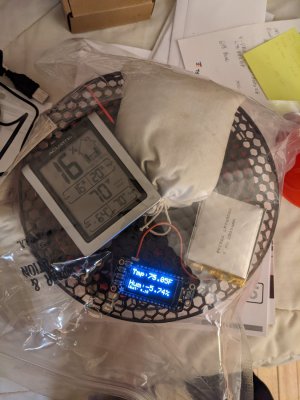

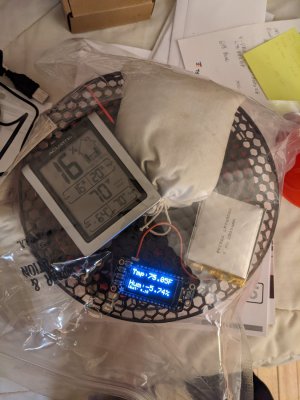

Have the PETG in a bag with lots of silica gel. I found the cheapo temperature/humidity sensors don't have very much resolution on the low end. Mine only has 4% steps. My filament as bottomed out at 16% RH in the bag. Cobbled together a temp/sensor with an Arduino and display and wrote half a page of code. Have it running off a battery. Hope to try it out to see if the RH in the bag really is 16%, or that is the lowest the cheapo unit will detect. The battery will run for a couple of days. Maybe I can get the Arduino to go into sleep mode to reduce the current draw and get even more battery life.

Well, within 2 minutes of being inserted in the bag, my sensor is reading an RH of 0.06%. I'd say the silica gel is working somewhat. The cheapo sensor is still reading/flickering between 16% and 20%. However, it would seem my sensor is lying too. Darn. It is reading -2%! How can you have negative relative humidity? It turns out the minimum output value of the HTU21DF is actually -6%. Due to process variations, the chip can output negative RH.

My lying? greenhouse temp/humidity gauge is reading 20% RH which is nonsense. I always knew the temperature was off on the sensor, and it turns out the humidity is suspect as well.

Just in the time it took to post the photo, the "lit" humidity sensor hit the minimum it can sense, or -6.00%. I am guessing it is dry in that bag. We shall see what it is in the morning...

Have the PETG in a bag with lots of silica gel. I found the cheapo temperature/humidity sensors don't have very much resolution on the low end. Mine only has 4% steps. My filament as bottomed out at 16% RH in the bag. Cobbled together a temp/sensor with an Arduino and display and wrote half a page of code. Have it running off a battery. Hope to try it out to see if the RH in the bag really is 16%, or that is the lowest the cheapo unit will detect. The battery will run for a couple of days. Maybe I can get the Arduino to go into sleep mode to reduce the current draw and get even more battery life.

Well, within 2 minutes of being inserted in the bag, my sensor is reading an RH of 0.06%. I'd say the silica gel is working somewhat. The cheapo sensor is still reading/flickering between 16% and 20%. However, it would seem my sensor is lying too. Darn. It is reading -2%! How can you have negative relative humidity? It turns out the minimum output value of the HTU21DF is actually -6%. Due to process variations, the chip can output negative RH.

My lying? greenhouse temp/humidity gauge is reading 20% RH which is nonsense. I always knew the temperature was off on the sensor, and it turns out the humidity is suspect as well.

Just in the time it took to post the photo, the "lit" humidity sensor hit the minimum it can sense, or -6.00%. I am guessing it is dry in that bag. We shall see what it is in the morning...

I think I should stop hijacking my own thread. Need to ask a more targeted question, so I will ask in an appropriately titled thread.