- Joined

- Sep 28, 2013

- Messages

- 4,318

Hi all,

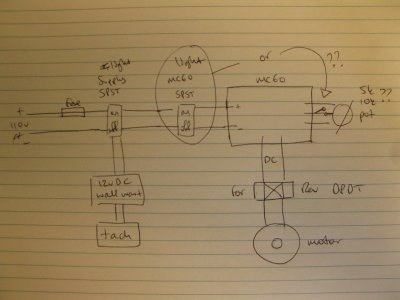

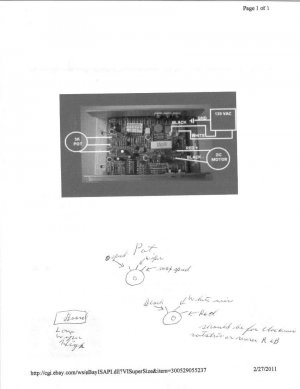

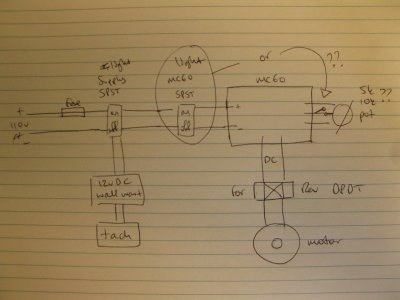

I was recently the lucky recipient of a treadmill motor and controller (MC60 by the looks of it) from the very generous jpfabricator and I'm idly thinking about how to wire it up instead of working. I also have another motor from a treadmill that I found at the side of the road if my wife doesn't end up using it. Both 1 to 1.25hp, one to go on the drill press, one to go on my 618. I'll be setting up both machines with tachs and I'd like both to be reversible once I've modded the motor flywheels so they don't unscrew themselves.

I've done a bunch of reading, but figured it would be best to have things checked out before ordering switches. 3 things I want to double check:

1) To reverse the motor I need a DPDT switch between the controller and the motor, wired so that the polarity to the motor is reversed. Switch would be wired Forward-STOP-Reverse. Can I do this with power to the controller or do I need to cut the power to the controller first, then change reverse the motor?

2) Speed control pot - 5k or 10k? Does it matter?

3) I've read that these controllers require the speed setting set to zero before starting each time. A work around is to either remove a resistor (not sure which one) or to put a SPST switch on the wiper wire to turn the motor on and off. Only downside would that this would leave the controller energised (see Q1)

Also, for that size motor, what current rating do I need for the switches. I'm thinking 10A from what I've read, but that's more guess than anything. Similarly, what fuse rating?

I've sketched out a wiring schematic, please find any flaws I've made!

thanks!

I was recently the lucky recipient of a treadmill motor and controller (MC60 by the looks of it) from the very generous jpfabricator and I'm idly thinking about how to wire it up instead of working. I also have another motor from a treadmill that I found at the side of the road if my wife doesn't end up using it. Both 1 to 1.25hp, one to go on the drill press, one to go on my 618. I'll be setting up both machines with tachs and I'd like both to be reversible once I've modded the motor flywheels so they don't unscrew themselves.

I've done a bunch of reading, but figured it would be best to have things checked out before ordering switches. 3 things I want to double check:

1) To reverse the motor I need a DPDT switch between the controller and the motor, wired so that the polarity to the motor is reversed. Switch would be wired Forward-STOP-Reverse. Can I do this with power to the controller or do I need to cut the power to the controller first, then change reverse the motor?

2) Speed control pot - 5k or 10k? Does it matter?

3) I've read that these controllers require the speed setting set to zero before starting each time. A work around is to either remove a resistor (not sure which one) or to put a SPST switch on the wiper wire to turn the motor on and off. Only downside would that this would leave the controller energised (see Q1)

Also, for that size motor, what current rating do I need for the switches. I'm thinking 10A from what I've read, but that's more guess than anything. Similarly, what fuse rating?

I've sketched out a wiring schematic, please find any flaws I've made!

thanks!