- Joined

- Feb 9, 2017

- Messages

- 5,521

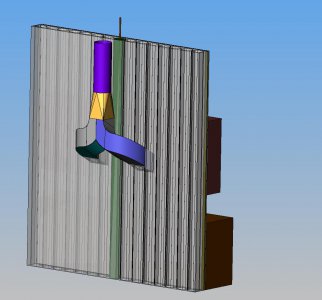

the YouTube AI made this one pop up and this guy did great job IMHO. As with anything it seems once you get the basics it’s all about tricks and shortcuts. HVAC ducting has always fascinated me and anytime someone wants to show you how to do something with just hand tools I’m all in.

He shows how to make a plenum box and introduces several super handy tools. The first one he calls bulldog snips which are short snips perfect for doing inside corners. The next one is using a screen spline tool that’s a double ended roller for installing screen splines when installing screen in frames. He uses it to do the stiffening X’s, very slick. I happened to have one and just replaced the screen on our back sliding glass door. And the last one was S lock which I’d never heard of which is used for joining sheetmetal. A comment was to make Pittsburgh locks which is similar but needs a brake to make where you can supposedly buy S lock somewhere. Another handy tool for 1” bends he had was a 15” slotted plate. I have a short 6” version and have used it a couple of times.

Hope someone finds this useful.

He shows how to make a plenum box and introduces several super handy tools. The first one he calls bulldog snips which are short snips perfect for doing inside corners. The next one is using a screen spline tool that’s a double ended roller for installing screen splines when installing screen in frames. He uses it to do the stiffening X’s, very slick. I happened to have one and just replaced the screen on our back sliding glass door. And the last one was S lock which I’d never heard of which is used for joining sheetmetal. A comment was to make Pittsburgh locks which is similar but needs a brake to make where you can supposedly buy S lock somewhere. Another handy tool for 1” bends he had was a 15” slotted plate. I have a short 6” version and have used it a couple of times.

Hope someone finds this useful.