the YouTube AI made this one pop up and this guy did great job IMHO. As with anything it seems once you get the basics it’s all about tricks and shortcuts. HVAC ducting has always fascinated me and anytime someone wants to show you how to do something with just hand tools I’m all in.

He shows how to make a plenum box and introduces several super handy tools. The first one he calls bulldog snips which are short snips perfect for doing inside corners. The next one is using a screen spline tool that’s a double ended roller for installing screen splines when installing screen in frames. He uses it to do the stiffening X’s, very slick. I happened to have one and just replaced the screen on our back sliding glass door. And the last one was S lock which I’d never heard of which is used for joining sheetmetal. A comment was to make Pittsburgh locks which is similar but needs a brake to make where you can supposedly buy S lock somewhere. Another handy tool for 1” bends he had was a 15” slotted plate. I have a short 6” version and have used it a couple of times.

Hope someone finds this useful.

NOTE:

DO NOT USE SINGLE FOLD FLANGE AT BOTTOM OF THE PLENUM!

I've seen more than a few homeowners and installers who tried to squeeze past a furnace in a tight location who opened up long gashes on the raw edge of a single fold flange. You must use a 1/2 double safety flange so that the outside edge is the rounded outside of the fold.

I installed ductwork for many years, including working my way thru university doing so. Upon graduation I started an hvac company. In Canada we do ducts far differently than you'll do in the US, so it is always funny to me when I see your metal duct practices and hear your terminology.

Typically we'd order metal fittings to be premade based on an hvac design, but on occasion I'd make my own either for an emergency, or when I was trying to fit a coil in a plenum and there was already cuts made in the plenum that compromised the integrity of the ducts.

We had enough tools to carry so like Alton Brown says "single use tools are fit for the garbage only" and that screen tool wont hold up over time. You put the brake or crease in the duct with a large slotted screw driver. It works a charm, never breaks, has a thousand usages, and is so handy prying under a plenum lip when you want to slide a replacement furnace under a hanging plenum during a re & re.

Up here we refer to that as "S" cleat, and it's partner as "drive" cleat. It is also too expensive and important to use in the manner shown.

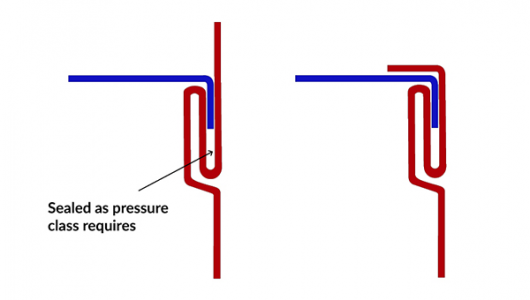

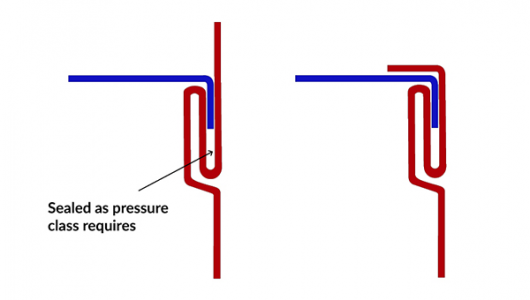

I always carried a stock of rectangular sheet metal that I'd run one of the short sides thru the Pittsburgh lock former so I could make up clean looking airtight plenums on a jobsite in seconds that cost far less. When you buy plain sheet metal to make ductwork yourself a legit supplier will put a pittsburg lock on one end for you for free. Two pieces of duct with a single fold in the middle and a short fold on the end make up a plenum with only two seams that are completely folded over for air tight seam as below.

The end cap simply has a double fold that gets pinched tight with folding pliers to make air tight seal, then secured with a few sheet metal screws. Cheapest, more efficient and air tight method possible.

That all said, if I were to build a new home that had ductwork now, I'd use fiberglass ductboard because such systems are far quieter, and more inherently air tight when installed properly so better air distribution and easier balancing with such systems. Ductboard is hard to acquire in southern Ontario and the closest training for installers was in Grand Rapids Michigan.

That said, I'd only have an HRV that was ducted, because I'd go with radiant heating and cooling with heat pumps

The exhaust goes through a fan in the attic and then vertically out through the roof......Bill