- Joined

- Jun 20, 2022

- Messages

- 235

I just purchased a round column mill rf25 or similar. It was RUNNING under 110v when purchased. Seller says it works fine. I saw it run.

Here's the problem....it appears to be actually wired for 220v. And it appears someone MAY have added aftermarket capacitors to the system.

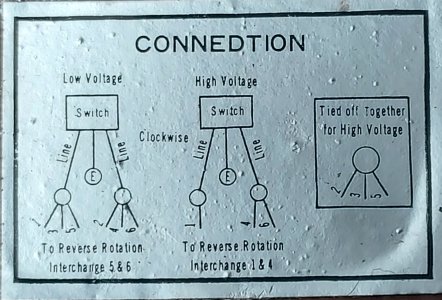

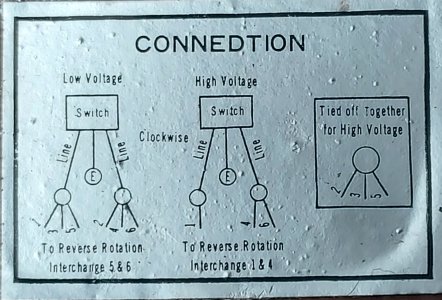

Here is the motor information:

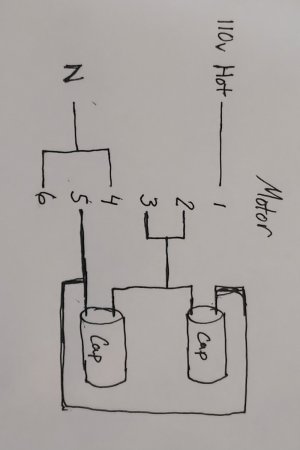

Here is what it looks like under the junction box

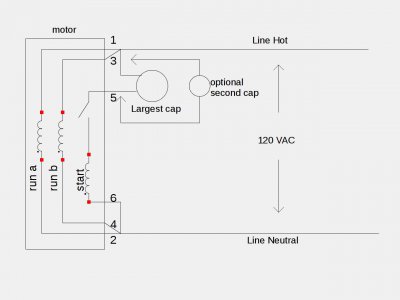

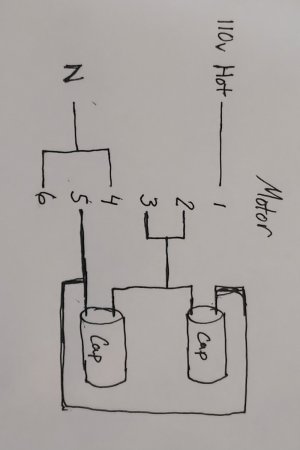

Here is the wiring diagram as it was wired when disassembled for transport.

Further to follow

Here's the problem....it appears to be actually wired for 220v. And it appears someone MAY have added aftermarket capacitors to the system.

Here is the motor information:

Here is what it looks like under the junction box

Here is the wiring diagram as it was wired when disassembled for transport.

Further to follow

Attachments

Last edited: