4

4GSR

Forum Guest

Register Today

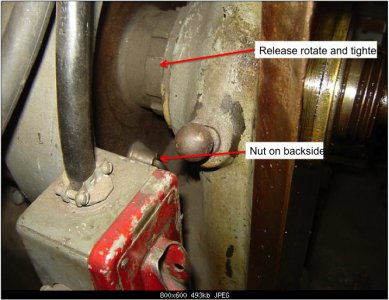

The sprocket shown in your picture is not original. It replaced a "silent chain" drive that B & S used back then. The split in the bronze bushing is to allow you to adjust the clearance in the spindle journals. The OD of the bronze bushing is on a taper. When you tighten that nut the ID of the bushing gets smaller.

To get the spindle out, you have to find the large set screw in the bull gear, where it secures itself to the spindle. Remove the set screw. Get you a 4 x 4 block and place on the back end of the spindle and drive out with a big hammer. Once it starts moving watch for the key in the ID of the bull gear. Rotate the spindle to top dead center. Back off the nut on the front bearing as far back as you can get it.

As you beat on the back end of the spindle, you will eject the front bearing along with the spindle. The bull gear and cone pulley will get left behind. Watch that cone pulley, its one big chunk of cast iron and is heavy! Once you get the spindle out, remove the key and slide the front bearing off the spindle.

My first mill was a Brown and Sharpe No. 3 mill built around 1910. It was very similar to the one in your picture.

To get the spindle out, you have to find the large set screw in the bull gear, where it secures itself to the spindle. Remove the set screw. Get you a 4 x 4 block and place on the back end of the spindle and drive out with a big hammer. Once it starts moving watch for the key in the ID of the bull gear. Rotate the spindle to top dead center. Back off the nut on the front bearing as far back as you can get it.

As you beat on the back end of the spindle, you will eject the front bearing along with the spindle. The bull gear and cone pulley will get left behind. Watch that cone pulley, its one big chunk of cast iron and is heavy! Once you get the spindle out, remove the key and slide the front bearing off the spindle.

My first mill was a Brown and Sharpe No. 3 mill built around 1910. It was very similar to the one in your picture.

.

.