- Joined

- Mar 26, 2018

- Messages

- 8,409

Hello,

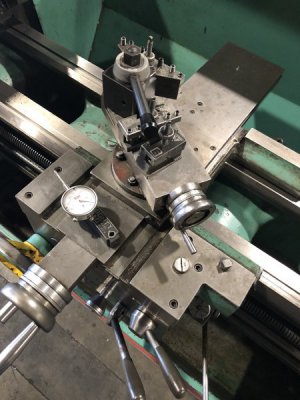

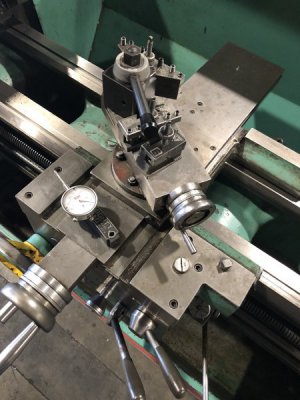

I just checked this lathe out.

Serial number is— 6/0015/05751, I am trying to determine the year of production.

Everything works great! I love the features of this lathe. The ways are clean and the saddle, compound are smooth and have little free play.

The brake works well, auto reverse, vari-speed is noisy but not overly so.

I like this old lathe.

Spindle taper is spotless.

What are the common issues to watch for?

I just checked this lathe out.

Serial number is— 6/0015/05751, I am trying to determine the year of production.

Everything works great! I love the features of this lathe. The ways are clean and the saddle, compound are smooth and have little free play.

The brake works well, auto reverse, vari-speed is noisy but not overly so.

I like this old lathe.

Spindle taper is spotless.

What are the common issues to watch for?