- Joined

- Sep 5, 2013

- Messages

- 3,207

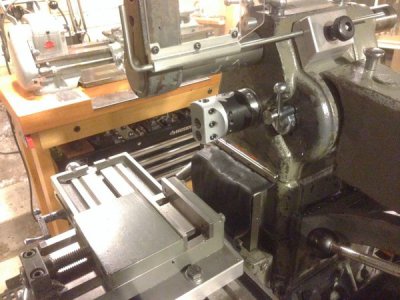

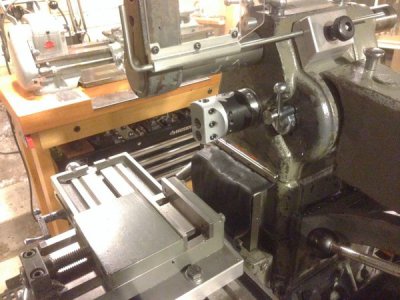

I bought this little boring head the other day, not that I desperately need one but it struck me at the time that the small size might work really nicely on the Atlas milling machine. The thing is, real estate on that machine is at a premium so I thought I could make an adapter to mount the boring head directly to the spindle.

It helps that the milling machine as well as my 618 lathe have exactly the same spindle noses, so it as a bit of a no brainer. I did the inside threads first, 1" - 10 tpi, and ran that up onto the lathe spindle much like making a nose protector.

Then I turned down the outside to diameter and finished length, and reduced the snout for the 1-1/2" - 18 thread on the boring head. I got nice fits on both threads even though it would be a big deal if they weren't. It's a boring head, it doesn't want to be concentric.

A hole in the edge of the register flange for a hook spanner, and away we go. Travel in "Z" is still going to be limited, but not as much as the alternative using a taper mount. That's my theory, anyway. Thanks for looking!

-frank

It helps that the milling machine as well as my 618 lathe have exactly the same spindle noses, so it as a bit of a no brainer. I did the inside threads first, 1" - 10 tpi, and ran that up onto the lathe spindle much like making a nose protector.

Then I turned down the outside to diameter and finished length, and reduced the snout for the 1-1/2" - 18 thread on the boring head. I got nice fits on both threads even though it would be a big deal if they weren't. It's a boring head, it doesn't want to be concentric.

A hole in the edge of the register flange for a hook spanner, and away we go. Travel in "Z" is still going to be limited, but not as much as the alternative using a taper mount. That's my theory, anyway. Thanks for looking!

-frank

I've never understood how one could stay clean at work . ( maybe I'm just a slob )

I've never understood how one could stay clean at work . ( maybe I'm just a slob )